Page 53 - The Complete Rigger’s Apprentice

P. 53

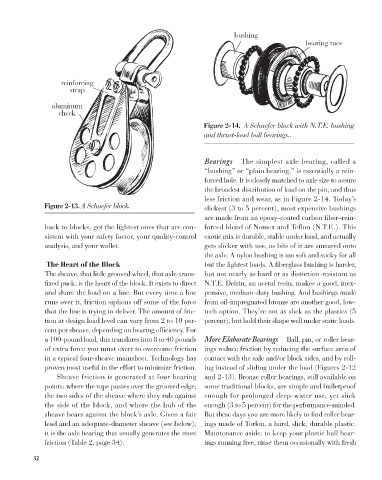

bushing

bearing race

reinforcing

strap

aluminum

cheek

Figure 2-14. A Schaefer block with N.T.E. bushing

and thrust-load ball bearings..

Bearings The simplest axle bearing, called a

“bushing” or “plain bearing,” is essentially a rein-

forced hole. It is closely matched to axle size to assure

the broadest distribution of load on the pin, and thus

less friction and wear, as in Figure 2-14. Today’s

Figure 2-13. A Schaefer block. slickest (3 to 5 percent), most expensive bushings

are made from an epoxy-coated carbon fiber–rein-

back to blocks, get the lightest ones that are con- forced blend of Nomex and Teflon (N.T.E.). This

sistent with your safety factor, your quality-control exotic mix is durable, stable under load, and actually

analysis, and your wallet. gets slicker with use, as bits of it are smeared onto

the axle. A nylon bushing is too soft and sticky for all

The Heart of the Block but the lightest loads. A fiberglass bushing is harder,

The sheave, that little grooved wheel, that axle-trans- but not nearly as hard or as distortion-resistant as

fixed puck, is the heart of the block. It exists to direct N.T.E. Delrin, an acetal resin, makes a good, inex-

and share the load on a line. But every time a line pensive, medium-duty bushing. And bushings made

runs over it, friction siphons off some of the force from oil-impregnated bronze are another good, low-

that the line is trying to deliver. The amount of fric- tech option. They’re not as slick as the plastics (5

tion at design load level can vary from 2 to 10 per- percent), but hold their shape well under static loads.

cent per sheave, depending on bearing efficiency. For

a 100-pound load, this translates into 8 to 40 pounds More Elaborate Bearings Ball, pin, or roller bear-

of extra force you must exert to overcome friction ings reduce friction by reducing the surface area of

in a typical four-sheave mainsheet. Technology has contact with the axle and/or block sides, and by roll-

proven most useful in the effort to minimize friction. ing instead of sliding under the load (Figures 2-12

Sheave friction is generated at four bearing and 2-13). Bronze roller bearings, still available on

points: where the rope passes over the grooved edge; some traditional blocks, are simple and bulletproof

the two sides of the sheave where they rub against enough for prolonged deep-water use, yet slick

the side of the block, and where the hub of the enough (3 to 5 percent) for the performance-minded.

sheave bears against the block’s axle. Given a fair But these days you are more likely to find roller bear-

lead and an adequate-diameter sheave (see below), ings made of Torlon, a hard, slick, durable plastic.

it is the axle bearing that usually generates the most Maintenance aside: to keep your plastic ball bear-

friction (Table 2, page 34). ings running free, rinse them occasionally with fresh

32