Page 53 - Ciaran Kinsella

P. 53

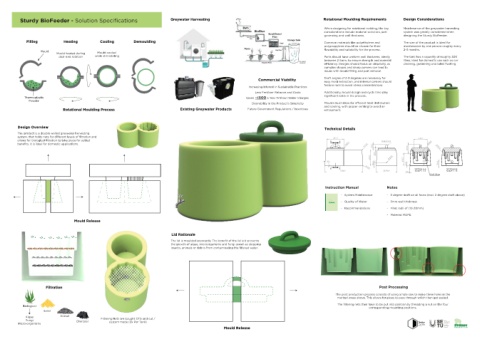

Sturdy BioFeeder - Solution Specifications Greywater Harvesting Rotational Moulding Requirements Design Considerations

When designing for rotational molding, the key Maintenance of the greywater harvesting

considerations include material selection, part system was greatly considered when

geometry, and wall thickness. designing the Sturdy BioFeeder.

Filling Heating Cooling Demoulding Common materials like polyethylene and The size of the product is ideal for

polypropylene should be chosen for their maintenance by one person roughly every

flowability and suitability for the process. 2-3 months.

Mould Mould cooled

Mould heated during

dual-axis rotation while still rotating Parts should have uniform wall thickness, ideally The tank has a capacity of roughly 300

between 2-5mm, to ensure strength and material litres, ideal for domestic use such as car

efficiency. Designs should focus on simplicity, as cleaning, gardening and toilet flushing.

complex shapes and sharp corners can lead to

issues with mould filling and part removal.

Commercial Viability Draft angles of 2-3 degrees are necessary for

easy mold extraction, and internal corners should

feature radii to avoid stress concentrations.

Increasing Interest in Sustainable Practices

Less Fertiliser Reliance and Costs Additionally, mould design and cycle time play

significant roles in the process.

Thermoplastic Saves ~€500 a Year Without Water Charges

Powder

Desirability in the Product’s Simplicity Moulds must allow for efficient heat distribution

and cooling, with proper venting to avoid air

Rotational Moulding Process Existing Greywater Products Future Government Regulations / Incentives entrapment.

Design Overview Technical Details

The product is a double walled greywater harvesting

system, that holds nets for different levels of filtration and 661.1 514.7

allows for biological filtration to take place for added B A TRUE R35.0

benefits. It is ideal for domestic applications. R20.0 R10.0 135.0 275.0 R45.0 90.0

70.0

600.0 25.0 475.0 93°

120.0 64.7 150.0

87°

B A R10.0 SECTION A-A SECTION B-B

1448.9 798.9 5.0 SCALE 1 : 15 SCALE 1 : 15

Draft 2deg

Instruction Manual Notes

- System Maintenance - 3 degree draft on all faces (excl. 2 degree draft above)

- Quality of Water - 5mm wall thickness

- Recommendations - Fillet radii of (10-20mm)

- Material: MDPE

Mould Release

Lid Rationale

The lid is moulded seperately. The benefit of the lid is it prevents

the growth of algae, microorganisms and fungi aswell as stopping

insects, animals or debris from contaminating the filtered water.

Filtration Post Processing

The post production process consists of using a hole saw to make three holes in the

marked areas above. This allows for pipes to pass through which then get sealed.

The filtering nets then have to be put into position by threading a nut on the four

Biological corresponding mounting positions.

Sand

Algae Gravel Filtering Nets are bought OTS and cut /

Fungi Charcoal

Micro-organisms custom made (3x Per Tank)

Mould Release