Page 4 - Ben Sweeney

P. 4

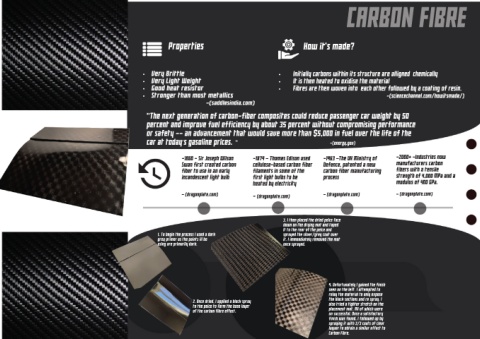

CARBON FIBRE

Properties How it's made?

• Very Brittle • Initially carbons within its structure are alligned chemically

• Very Light Weight • It is then heated to oxidise the material

• Good heat resistor • Fibres are then woven into each other followed by a coating of resin.

• Stronger than most metallics -(sciencechannel.com/howitsmade/)

-(saddlesindia.com)

“The next generation of carbon-fiber composites could reduce passenger car weight by 50

percent and improve fuel efficiency by about 35 percent without compromising performance

or safety -- an advancement that would save more than $5,000 in fuel over the life of the

car at today’s gasoline prices. ” -(energy.gov)

-1860 - Sir Joseph Wilson -1879 – Thomas Edison used -1963 –The UK Ministry of -2000+ -Industries now

Swan first created carbon cellulose-based carbon fiber Defence, patented a new manufacturers carbon

fiber to use in an early filaments in some of the carbon fiber manufacturing fibers with a tensile

incandescent light bulb first light bulbs to be process strength of 4,000 MPa and a

heated by electricity modulus of 400 GPa.

– (dragonplate.com) - (dragonplate.com) – (dragonplate.com) – (dragonplate.com)

3. I then placed the dried peice face

down on the drying mat and taped

it to the rear of the peice and

1. To begin the process I used a dark sprayed the silver/grey coat over

grey primer as the paints ill be it. I immeadiately removed the mat

using are primarily dark. once sprayed.

4. Unfortunately I gained the finish

seen on the left. I attempted to

relay the material to only expose

2. Once dried, I applied a black spray the black sections and re spray. I

to the peice to form the base layer also tried a tighter stretch on the

of the carbon fibre effect. placement mat. All of which were

un successful. Once a satisfactory

finish was found, I followed up by

spraying it with 2/3 coats of clear

laquer to obtain a similar effect to

Carbon Fibre.