Page 6 - Ben Sweeney

P. 6

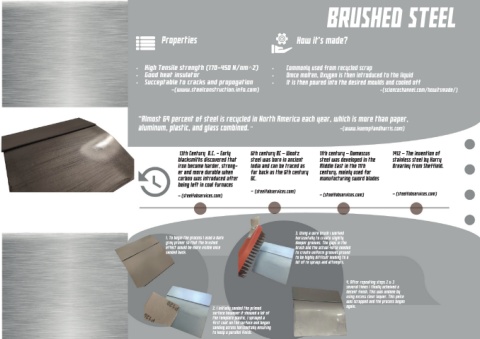

BRUSHED STEEL

Properties How it's made?

• High Tensile strength (170-450 N/nm^2) • Commonly used from recycled scrap

• Good heat insulator • Omce molten, Oxygen is then introduced to the liquid

• Succeptable to cracks and propogation • It is then poured into the desired moulds and cooled off

-(www.steelconstruction.info.com) -(sciencechannel.com/howitsmade/)

“Almost 69 percent of steel is recycled in North America each year, which is more than paper,

aluminum, plastic, and glass combined. “ -(www.kaempfandharris.com)

13th Century B.C. - Early 6th century BC – Wootz 11th century – Damascus 1912 – The invention of

blacksmiths discovered that steel was born in ancient steel was developed in the stainless steel by Harry

iron become harder, strong- India and can be traced as Middle East in the 11th Brearley from Sheffield.

er and more durable when far back as the 6th century century, mainly used for

carbon was introduced after BC. manufacturing sword blades

being left in coal furnaces

- (steelfabservices.com)

– (steelfabservices.com) – (steelfabservices.com) – (steelfabservices.com)

3. Using a wire brush i worked

1. To begin the process I used a dark horizontally to create slightly

grey primer so that the brushed deeper grooves. The gaps in the

effect would be more visible once brush and the actual force needed

sanded back. to create uniform grooves proved

to be highly difficult leading to a

lot of re sprays and attempts.

4. After repeating steps 2 & 3

several times i finally acheived a

decent finish. This was undone by

using excess clear laquer. This peice

was scrapped and the process began

2. I initially sanded the primed again.

surface however it showed a lot of

the template plastic. I sprayed a

first coat on the surface and began

sanding across horizontally ensuring

to keep a parallel finish.