Page 40 - Imprint-magazine june-Issue

P. 40

volume is as low as 20% of the maxi-

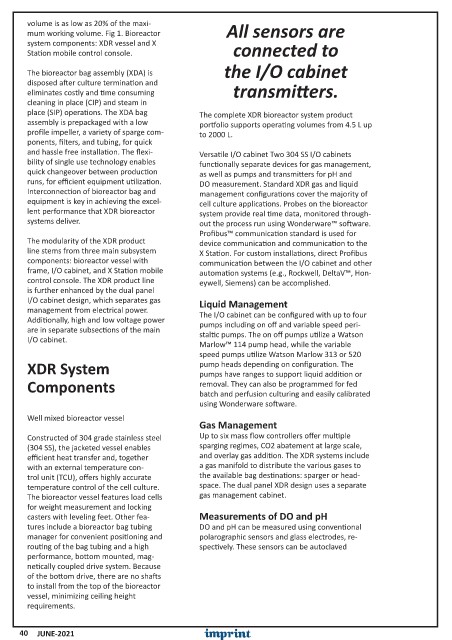

mum working volume. Fig 1. Bioreactor All sensors are

system components: XDR vessel and X connected to

Station mobile control console.

The bioreactor bag assembly (XDA) is the I/O cabinet

disposed after culture termination and

eliminates costly and time consuming transmitters.

cleaning in place (CIP) and steam in

place (SIP) operations. The XDA bag The complete XDR bioreactor system product

assembly is prepackaged with a low portfolio supports operating volumes from 4.5 L up

profile impeller, a variety of sparge com- to 2000 L.

ponents, filters, and tubing, for quick

and hassle free installation. The flexi- Versatile I/O cabinet Two 304 SS I/O cabinets

bility of single use technology enables functionally separate devices for gas management,

quick changeover between production as well as pumps and transmitters for pH and

runs, for efficient equipment utilization. DO measurement. Standard XDR gas and liquid

Interconnection of bioreactor bag and management configurations cover the majority of

equipment is key in achieving the excel- cell culture applications. Probes on the bioreactor

lent performance that XDR bioreactor system provide real time data, monitored through-

systems deliver. out the process run using Wonderware™ software.

Profibus™ communication standard is used for

The modularity of the XDR product device communication and communication to the

line stems from three main subsystem X Station. For custom installations, direct Profibus

components: bioreactor vessel with communication between the I/O cabinet and other

frame, I/O cabinet, and X Station mobile automation systems (e.g., Rockwell, DeltaV™, Hon-

control console. The XDR product line eywell, Siemens) can be accomplished.

is further enhanced by the dual panel

I/O cabinet design, which separates gas Liquid Management

management from electrical power. The I/O cabinet can be configured with up to four

Additionally, high and low voltage power pumps including on off and variable speed peri-

are in separate subsections of the main staltic pumps. The on off pumps utilize a Watson

I/O cabinet.

Marlow™ 114 pump head, while the variable

speed pumps utilize Watson Marlow 313 or 520

XDR System pump heads depending on configuration. The

pumps have ranges to support liquid addition or

Components removal. They can also be programmed for fed

batch and perfusion culturing and easily calibrated

using Wonderware software.

Well mixed bioreactor vessel

Gas Management

Constructed of 304 grade stainless steel Up to six mass flow controllers offer multiple

(304 SS), the jacketed vessel enables sparging regimes, CO2 abatement at large scale,

efficient heat transfer and, together and overlay gas addition. The XDR systems include

with an external temperature con- a gas manifold to distribute the various gases to

trol unit (TCU), offers highly accurate the available bag destinations: sparger or head-

temperature control of the cell culture. space. The dual panel XDR design uses a separate

The bioreactor vessel features load cells gas management cabinet.

for weight measurement and locking

casters with leveling feet. Other fea- Measurements of DO and pH

tures include a bioreactor bag tubing DO and pH can be measured using conventional

manager for convenient positioning and polarographic sensors and glass electrodes, re-

routing of the bag tubing and a high spectively. These sensors can be autoclaved

performance, bottom mounted, mag-

netically coupled drive system. Because

of the bottom drive, there are no shafts

to install from the top of the bioreactor

vessel, minimizing ceiling height

requirements.

40 JUNE-2021