Page 43 - Imprint-magazine june-Issue

P. 43

Qualification support

The XDR bioreactor systems are designed

for use in environments that require 21

CFR Part 11 and GAMP™ 5. The systems are

delivered with an operating manual, system

specification, drawings to support qualifica-

tion, and major component documentation.

Industry standard installation and operation DELIVER MORE, FASTER

qualification (IQ/OQ) packages are available

as an option. Increase throughput:

Applications more programs, more molecules

XDR cell culture bioreactor systems have Increase productivity:

successfully been used to cultivate a wide

range of cell types and organisms including

CHO cells, Vero cells, HEK293, and MDCK more product per batch

cells. In addition, a fermentor system is

available for microbial applications includ- Increase capacity:

ing E. coli, Pseudomonas spp., and yeast.

XDR bioreactor systems can be operated in more batches per facility

batch, fed batch, and perfusion (or chemo-

stat) modes. Bioreactor bag design can be EXECUTE HIGH ROI BUSINESS

process dependent, requiring customization DECISIONS

for proper use and performance.

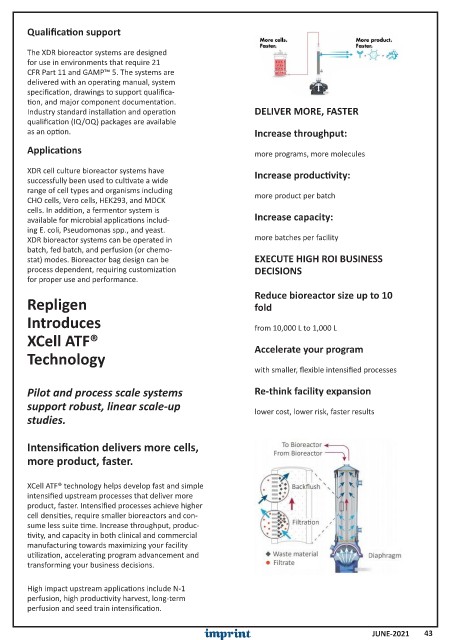

Repligen Reduce bioreactor size up to 10

fold

Introduces from 10,000 L to 1,000 L

XCell ATF®

Technology Accelerate your program

with smaller, flexible intensified processes

Pilot and process scale systems Re-think facility expansion

support robust, linear scale-up lower cost, lower risk, faster results

studies.

Intensification delivers more cells,

more product, faster.

XCell ATF® technology helps develop fast and simple

intensified upstream processes that deliver more

product, faster. Intensified processes achieve higher

cell densities, require smaller bioreactors and con-

sume less suite time. Increase throughput, produc-

tivity, and capacity in both clinical and commercial

manufacturing towards maximizing your facility

utilization, accelerating program advancement and

transforming your business decisions.

High impact upstream applications include N-1

perfusion, high productivity harvest, long-term

perfusion and seed train intensification.

JUNE-2021 43