Page 46 - Imprint-magazine june-Issue

P. 46

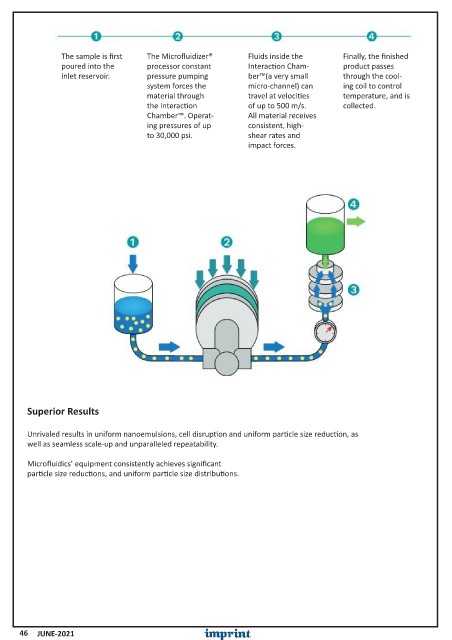

The sample is first The Microfluidizer® Fluids inside the Finally, the finished

poured into the processor constant Interaction Cham- product passes

inlet reservoir. pressure pumping ber™(a very small through the cool-

system forces the micro-channel) can ing coil to control

material through travel at velocities temperature, and is

the Interaction of up to 500 m/s. collected.

Chamber™. Operat- All material receives

ing pressures of up consistent, high-

to 30,000 psi. shear rates and

impact forces.

Superior Results

Unrivaled results in uniform nanoemulsions, cell disruption and uniform particle size reduction, as

well as seamless scale-up and unparalleled repeatability.

Microfluidics’ equipment consistently achieves significant

particle size reductions, and uniform particle size distributions.

46 JUNE-2021