Page 45 - May

P. 45

NEW TECHNOLOGY

Glow discharge

Glow discharge is an independent electric discharge in a gas with cold electrodes at currents

of 10-5 - 1.0 A and low pressure (5 • 10-2-103 Pa), which has a characteristic structure in the

form of alternating luminous areas of different colors and different intensity of luminescence.

Its distinctive feature is the existence of a layer near the cathode with a large positive space

charge, a strong field at the surface and a significant drop in potential of 100 - 400 V and

more. The glow discharge got its name from the presence of the so-called glow on one of the

electrodes (cathode).

One of the applications of the glow discharge is the technology of plasma chemical-

thermal treatment of metals, which are designed to increase the hardness, wear resistance,

fatigue strength, scuff resistance, heat resistance and corrosion resistance due to saturation

of the surface of the processed products with nitrogen, carbon, boron, cadmium and several

elements at the same time. During processing, the products are immersed in the plasma

of a glow discharge that burns between the cathode (products) and the anode (walls of the

vacuum chamber) and contains the necessary saturating element. Positively charged ions of

the saturating element under the action of an electric field are accelerated towards the product,

bombarded and penetrated into their surface layer. In this case, the energy of ions is thousands

of times higher than the energy of atoms during gas chemical-thermal treatment. The heating

temperature of products during processing is 300 - 600 °C.

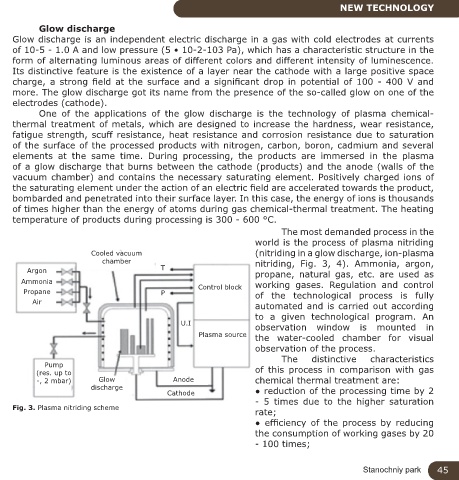

The most demanded process in the

world is the process of plasma nitriding

Cooled vacuum (nitriding in a glow discharge, ion-plasma

chamber nitriding, Fig. 3, 4). Ammonia, argon,

Argon Т propane, natural gas, etc. are used as

Ammonia working gases. Regulation and control

Propane Р Control block of the technological process is fully

Air

automated and is carried out according

to a given technological program. An

U.I observation window is mounted in

Plasma source the water-cooled chamber for visual

observation of the process.

The distinctive characteristics

Pump

(res. up to of this process in comparison with gas

-, 2 mbar) Glow Anode chemical thermal treatment are:

discharge ● reduction of the processing time by 2

Cathode

- 5 times due to the higher saturation

Fig. 3. Plasma nitriding scheme

rate;

● efficiency of the process by reducing

the consumption of working gases by 20

- 100 times;

Stanochniy park 45