Page 13 - Stanochny park

P. 13

METALWORKING EQUIPMENT AND TOOLS

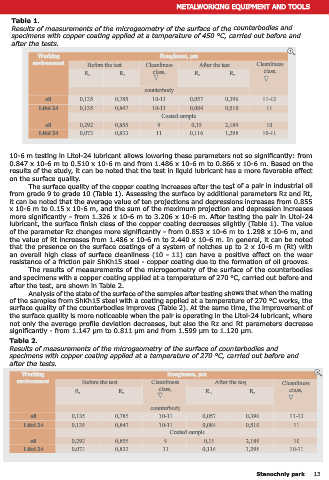

Table 1.

Results of measurements of the microgeometry of the surface of the counterbodies and

specimens with copper coating applied at a temperature of 450 °C, carried out before and

after the tests.

Working Roughness, μm

environment Before the test Cleanliness After the test Cleanliness After the test

class, class,

Ra Rz Ra Rz

counterbody

oil 0,135 0,785 10-11 0,057 0,396 11-12

Litol 24 0,135 0,847 10-11 0,084 0,510 11

Coated sample

oil 0,292 0,855 9 0,15 2,189 10

Litol 24 0,073 0,833 11 0,116 1,298 10-11

10-6 m testing in Litol-24 lubricant allows lowering these parameters not so significantly: from

0.847 x 10-6 m to 0.510 x 10-6 m and from 1.486 x 10-6 m to 0.866 x 10-6 m. Based on the

results of the study, it can be noted that the test in liquid lubricant has a more favorable effect

on the surface quality.

The surface quality of the copper coating increases after the test of a pair in industrial oil

from grade 9 to grade 10 (Table 1). Assessing the surface by additional parameters Rz and Rt,

it can be noted that the average value of ten projections and depressions increases from 0.855

x 10-6 m to 0.15 x 10-6 m, and the sum of the maximum projection and depression increases

more significantly - from 1.326 x 10-6 m to 3.206 x 10-6 m. After testing the pair in Litol-24

lubricant, the surface finish class of the copper coating decreases slightly (Table 1). The value

of the parameter Rz changes more significantly - from 0.853 x 10-6 m to 1.298 x 10-6 m, and

the value of Rt increases from 1.486 x 10-6 m to 2.440 x 10-6 m. In general, it can be noted

that the presence on the surface coatings of a system of notches up to 2 x 10-6 m (Rt) with

an overall high class of surface cleanliness (10 - 11) can have a positive effect on the wear

resistance of a friction pair ShKh15 steel - copper coating due to the formation of oil grooves.

The results of measurements of the microgeometry of the surface of the counterbodies

and specimens with a copper coating applied at a temperature of 270 °C, carried out before and

after the test, are shown in Table 2.

Analysis of the state of the surface of the samples after testing shows that when the mating

of the samples from ShKh15 steel with a coating applied at a temperature of 270 °C works, the

surface quality of the counterbodies improves (Table 2). At the same time, the improvement of

the surface quality is more noticeable when the pair is operating in the Litol-24 lubricant, where

not only the average profile deviation decreases, but also the Rz and Rt parameters decrease

significantly - from 1.147 μm to 0.811 μm and from 1.599 μm to 1.120 μm.

Table 2.

Results of measurements of the microgeometry of the surface of counterbodies and

specimens with copper coating applied at a temperature of 270 °C, carried out before and

after the tests.

Working Roughness, μm

environment Before the test Cleanliness After the test Cleanliness

class, class,

Ra Rz Ra Rz

counterbody

oli 0,135 0,785 10-11 0,057 0,396 11-12

Litol 24 0,135 0,847 10-11 0,084 0,510 11

Coated sample

oil 0,292 0,855 9 0,15 2,189 10

Litol 24 0,073 0,833 11 0,116 1,298 10-11

Stanochniy park 13