Page 16 - Stanochny park

P. 16

METALWORKING EQUIPMENT AND TOOLS

Properties of Spark Plasma Sintered Carbide

In metalworking, a tool is widely used, equipped with

replaceable polyhedral inserts (RPI) from cutting materials.

Requirements of high durability are imposed on RPI, that

is, stable wear resistance in a given time interval. The

most common RPIs are made of sintered hard alloys,

the resistance of which depends on the grain size

of their structure - the smaller the grain, the higher

the hardness and wear resistance while ensuring a

sufficiently high bending strength [1, 2].

An important consequence of the reduction in

grain size is the achievement of special sharpness of the cutting

edges with a rounding radius of less than 2 μm. In addition, with

a decrease in the grain size, the amount of heat that goes into the

chips increases, which reduces its supply to the tool and the work

piece [3]. Spark plasma sintering (SPS) is one of the directions for

creating products with nanoscale "grain size", as

stated in a number of works [4, 5].

Determined the possibility of using

alloys, obtained by SPS, for cutting structural

materials. For this purpose, 6 work pieces with a diameter of

40 and a thickness of 5 mm were sintered from a mixture of

nanopowders, including 94 wt % WC and 6 wt % Co, using

an SPS unit manufactured by FCT Systeme (Germany) in

the temperature range from 1100 to 1500 °C. Other

sintering modes:

a) sintering speed V = 100 °C / min;

b) pressure P = 40 MPa;

c) holding time 2 min.

The characteristics of the materials obtained are

given in [6].

Cutting inserts, the types of which are shown in

Table 1, were cut from the sintered SPS billets on an

AgieCharmilles Cut30P wire EDM machine.

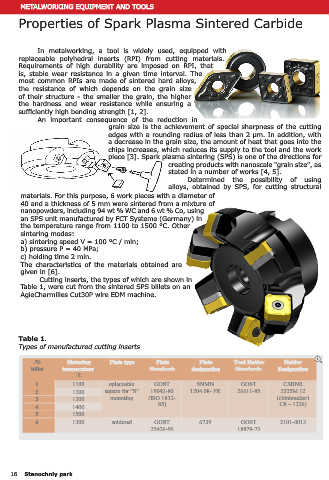

Table 1.

Types of manufactured cutting inserts

№ Sintering Plate type Plate Plate Tool Holder Holder

billet temperature, Standards designation Standards Designation

˚С

1 1100 eplaceable GOST SNMN GOST CSBNR

2 1200 square for "S" 19042-80 1204 08- FR 26611-85 2525M 12

3 1300 mounting (ISO 1832- (chipbreaker)

4 1400 85) С8 – 1226)

5 1500

6 1300 soldered GOST 6739 GOST 2101-0013

25426-90 18879-73

16 Stanochniy park