Page 20 - Stanochny park

P. 20

METALWORKING EQUIPMENT AND TOOLS

With a material thickness of less than 16 mm, this process

proceeds normally. In cases where the insertion occurs on the

surface of the sheets more than 16 mm, the following negative

phenomena from an operational point of view occur.

The cut cavity is not formed instantly, the electric arc

closes on the upper part of the billet and begins to melt the

metal, the gas blows out the molten metal upward, after

removing a certain amount of material, and an entrance crater

is formed. This is blind cavity of the cut, in the crater the arc

closes already on the side wall, removal the molten material

still proceeds upward until the entire thickness of the metal

is completely melted. This creates a typical cut cavity from

which molten metal is removed downward. The duration of the

transition from the crater to the normal cutting cavity can take

3 - 7 seconds, and this time is enough to cause some damage

to the components of the plasmatron.

To minimize the consequences of this negative

phenomenon, an algorithm of actions was developed that

allows burning thick billets with minimal consequences.

First, the perforation delay time should be increased. This

is the time during which the plasmatron burns through the inlet.

In addition, increase the arc current and gas pressure during

piercing by 15 - 20% of the manufacturer’s recommended

values for a specific billet thickness.

Second, a protective coating should be used to cap,

silicone grease and spray for semi-automatic welding machines

showed acceptable results.

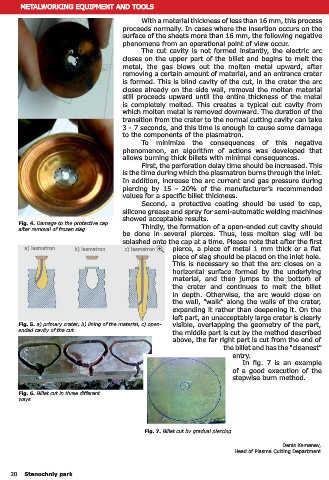

Fig. 4. Damage to the protective cap Thirdly, the formation of a open-ended cut cavity should

after removal of frozen slag.

be done in several pierces. Thus, less molten slag will be

splashed onto the cap at a time. Please note that after the first

a) lasmatron b) lasmatron c) lasmatron pierce, a piece of metal 1 mm thick or a flat

piece of slag should be placed on the inlet hole.

This is necessary so that the arc closes on a

horizontal surface formed by the underlying

material, and then jumps to the bottom of

the crater and continues to melt the billet

in depth. Otherwise, the arc would close on

the wall, "walk" along the walls of the crater,

expanding it rather than deepening it. On the

left part, an unacceptably large crater is clearly

Fig. 5. a) primary crater, b) lining of the material, c) open- visible, overlapping the geometry of the part,

ended cavity of the cut. the middle part is cut by the method described

above, the far right part is cut from the end of

the billet and has the "cleanest"

entry.

In fig. 7 is an example

of a good execution of the

stepwise burn method.

Fig. 6. Billet cut in three different

ways.

Fig. 7. Billet cut by gradual piercing.

Denis Kamenev,

Head of Plasma Cutting Department

20 Stanochniy park