Page 14 - RCM - A practical Guide_V1

P. 14

RCM - A Practical Guide

RCM EXPLAINED

Before we move on to explain the RCM process in detail, lets examine what gave the method its name.

CONDITIONAL PROBABILITY OF FAILURE

The most useful measure of the age-reliability relationship is the probability that an item entering a

given age interval will fail during that interval. This is usually called the Conditional Probability of

Failure (Cpf).

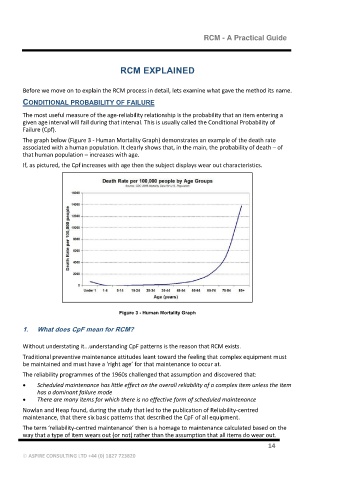

The graph below (Figure 3 - Human Mortality Graph) demonstrates an example of the death rate

associated with a human population. It clearly shows that, in the main, the probability of death – of

that human population – increases with age.

If, as pictured, the Cpf increases with age then the subject displays wear out characteristics.

Figure 3 - Human Mortality Graph

1. What does CpF mean for RCM?

Without understating it...understanding CpF patterns is the reason that RCM exists.

Traditional preventive maintenance attitudes leant toward the feeling that complex equipment must

be maintained and must have a ‘right age’ for that maintenance to occur at.

The reliability programmes of the 1960s challenged that assumption and discovered that:

• Scheduled maintenance has little effect on the overall reliability of a complex item unless the item

has a dominant failure mode

• There are many items for which there is no effective form of scheduled maintenance

Nowlan and Heap found, during the study that led to the publication of Reliability-centred

maintenance, that there six basic patterns that described the CpF of all equipment.

The term ‘reliability-centred maintenance’ then is a homage to maintenance calculated based on the

way that a type of item wears out (or not) rather than the assumption that all items do wear out.

14

© ASPIRE CONSULTING LTD +44 (0) 1827 723820