Page 62 - DBP5043

P. 62

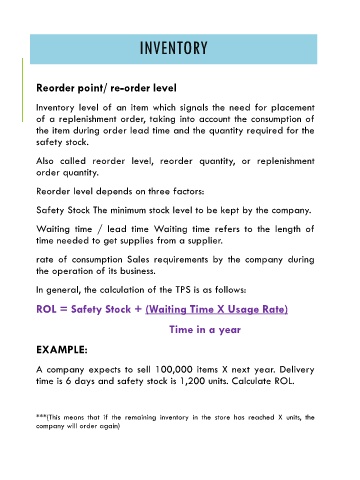

INVENTORY

Reorder point/ re-order level

Inventory level of an item which signals the need for placement

of a replenishment order, taking into account the consumption of

the item during order lead time and the quantity required for the

safety stock.

Also called reorder level, reorder quantity, or replenishment

order quantity.

Reorder level depends on three factors:

Safety Stock The minimum stock level to be kept by the company.

Waiting time / lead time Waiting time refers to the length of

time needed to get supplies from a supplier.

rate of consumption Sales requirements by the company during

the operation of its business.

In general, the calculation of the TPS is as follows:

ROL = Safety Stock + (Waiting Time X Usage Rate)

Time in a year

EXAMPLE:

A company expects to sell 100,000 items X next year. Delivery

time is 6 days and safety stock is 1,200 units. Calculate ROL.

***(This means that if the remaining inventory in the store has reached X units, the

company will order again)