Page 17 - Deydier UNDERSTANDING CHINESE ARCHAIC BRONZES

P. 17

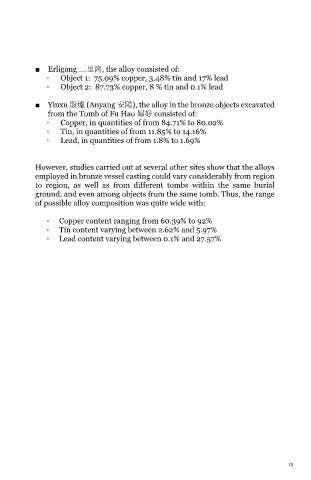

Copper being the major component of bronze, it was procured by the ■ Erligang 二里崗, the alloy consisted of:

ancient Chinese both from open-air and subterranean mines. A great ◦ Object 1: 75.09% copper, 3.48% tin and 17% lead

number of these ancient mines have been rediscovered in recent years, ◦ Object 2: 87.73% copper, 8 % tin and 0.1% lead

among them a mine in the present-day province of Hebei 河北省 at

Tonglu 桐廬, south of present-day Beijing 北京. These ancient mines ■ Yinxu 殷墟 (Anyang 安陽), the alloy in the bronze objects excavated

consisted of either vertical pits, or horizontal or sloping subterranean from the Tomb of Fu Hao 婦好 consisted of:

tunnels. Ancient texts record more than 1,000 km of such tunnels in ◦ Copper, in quantities of from 84.71% to 80.02%

Hebei 河北 province alone. ◦ Tin, in quantities of from 11.85% to 14.16%

◦ Lead, in quantities of from 1.8% to 1.69%

Bronze in Ancient China

However, studies carried out at several other sites show that the alloys

Bronze, which is generally a mixture of copper and tin, could also be, in employed in bronze vessel casting could vary considerably from region

ancient China, an alloy composed of copper and lead, an alloy of copper to region, as well as from different tombs within the same burial

and tin only, or an alloy of copper, tin and lead. The especially high ground, and even among objects from the same tomb. Thus, the range

quality of vessels produced in ancient China from this alloy is proof of possible alloy composition was quite wide with:

of the purity of the copper in the alloy and of the success of ancient

Chinese artisans in controlling the temperature needed for melting the ◦ Copper content ranging from 60.39% to 92%

alloy, for the higher the proportion of copper in the alloy, the higher ◦ Tin content varying between 2.62% and 5.97%

the temperature must be raised. Thus a temperature of 960 degrees ◦ Lead content varying between 0.1% and 27.57%

is needed for a copper, tin and lead alloy containing more copper and

only 15% tin, whereas a temperature of only 810 degrees is needed for

an alloy containing less copper and 25% tin. The presence of lead in the

alloy allows a lowering of the temperature necessary to melt the metal

alloy.

Metallurgical analyses carried out on scientifically excavated ancient

th

th

th

Chinese bronze vessels at the Erlitou 二里頭 sites (circa 19 – 17 /16

centuries B.C.) at Yanshi 偃師, Henan 河南 province, and at Erligang

二里崗 period sites at Zhengzhou 鄭州, Henan 河南 province (early

th

th

Shang 商 dynasty circa 17 /16th – 14 centuries B.C.) and at the Yinxu

殷墟 sites (second part of the Shang 商 dynasty, circa 14 – 12 /11

th

th

th

centuries B.C.) at Anyang 安陽, Henan 河南 province show that the

alloy used in producing bronze vessels cast during these early periods

was not consistent.

Thus at:

■ Erlitou 二里頭, the alloy consisted of

◦ Vessel v/1: 92% copper and 7% tin

◦ Vessel v/2: 91.89% copper, 2.62% tin and 2.34% lead

14 15