Page 21 - Deydier UNDERSTANDING CHINESE ARCHAIC BRONZES

P. 21

After cooling off, the bronze vessel, which was usually cast upside-down,

was removed from the mold. On many bronze vessels mold marks or

seams can be detected on a close inspection of the piece, but on pieces

of the highest quality, such marks are barely perceptible, since they are

often located at the junctions where the vertical lines of the vessel join.

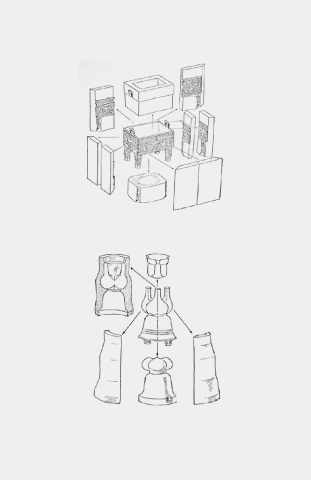

Lost wax casting

This technique was first utilized in China around the 5 century B.C. in

th

the late Spring and Autumn 春秋 period. It consisted of:

1. Making a wax model on a brick-clay core of the same size as the

desired bronze vessel.

The decoration was then either carved by hand or stamp printed

with the aid of a matrix, which was usually the case for the repetitive

motifs of the Warring States 戰國 period (circa 475 – 221 B.C.).

2. Once the decoration was completed, the wax object was bathed,

once, in a small layer of liquid clay containing a resistant substance,

then in several more layers of regular clay which thus formed a

covering around the vessel.

3. On contact, the liquid bronze poured into the space between the

core and the outer clay covering caused the wax to melt and escape

through special openings left in the outer covering by the craftsman

and simultaneously filled the space left between the matrix and the

outer clay covering and took the form of the desired object.

4. After the metal cooled off, the mold around the bronze vessel was

broken off, freeing the bronze vessel, which was retouched and

manually finished wherever necessary.

18 19