Page 18 - Deydier UNDERSTANDING CHINESE ARCHAIC BRONZES

P. 18

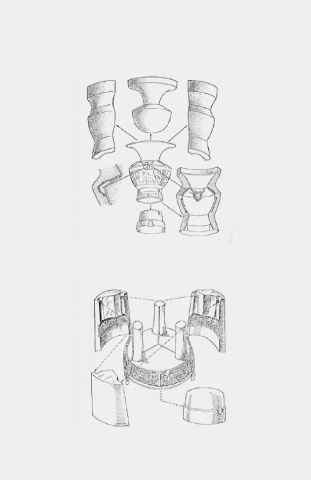

Casting Techniques

Scientific archaeological excavations undertaken between 1928 and

1938 at the site of the ancient Shang 商 royal cemetery at Yinxu 殷

墟 in present-day Anyang 安陽 in Henan 河南 province and years

later at early Shang 商初期 sites at Zhengzhou 鄭州 and Erligang 二

里崗 in Henan 河南 province and at Panlongcheng 盤龍城 in Hubei 湖

北 province all revealed the existence of fragments of grey terracotta

molds used during the casting of bronze vessels.

These discoveries proved beyond a doubt that in the beginning of bronze

production in ancient china, bronzes were produced by multi-mold

casting, and not by the lost wax process, as specialists had previously

believed.

Multi-mould casting

The fragments of molds found at the above-mentioned sites enabled the

archeologists of the Academia Sinica 國立中央研究院 led by Professor

Li Ji 李濟 to establish with precision the different steps taken by the

artisans of the Shang 商 and Zhou 周 dynasties in the production of a

bronze vessel:

1. First a matrix of the desired vessel was made in terracotta. The

terracotta matrix was an exact copy of the final product, bearing

the same degree of fineness and beauty of decoration desired for

the bronze vessel.

2. The matrix was then completely covered over with fine thin layers

of clay to a thickness of 15 mm, which would eventually serve as the

negative.

3. After baking, the negative was cut off in pieces, which would then

become the parts of the mold.

4. These parts were then assembled and set in a tub or tray of sand.

5. Then a plain inner core was made and surrounded by the pieces

of the mold, which were placed in such a way as to leave an empty

space of from 5 to 15 mm between the core and the assembled

pieces of the mold surrounding it.

6. Finally, hot liquid bronze was poured into the space between the

core and the assembled mold.

16 17