Page 5 - VT Vibe Newsletter June 28 2023 (Final)

P. 5

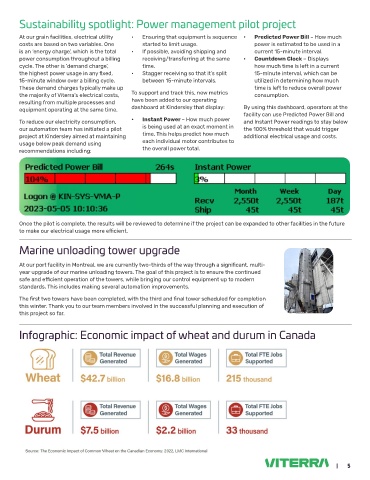

Sustainability spotlight: Power management pilot project

At our grain facilities, electrical utility • Ensuring that equipment is sequence • Predicted Power Bill – How much

costs are based on two variables. One started to limit usage. power is estimated to be used in a

is an ‘energy charge’, which is the total • If possible, avoiding shipping and current 15-minute interval.

power consumption throughout a billing receiving/transferring at the same • Countdown Clock – Displays

cycle. The other is ‘demand charge’, time. how much time is left in a current

the highest power usage in any fixed, • Stagger receiving so that it’s split 15-minute interval, which can be

15-minute window over a billing cycle. between 15-minute intervals. utilized in determining how much

These demand charges typically make up time is left to reduce overall power

the majority of Viterra’s electrical costs, To support and track this, new metrics consumption.

resulting from multiple processes and have been added to our operating

equipment operating at the same time. dashboard at Kindersley that display: By using this dashboard, operators at the

facility can use Predicted Power Bill and

To reduce our electricity consumption, • Instant Power – How much power and Instant Power readings to stay below

our automation team has initiated a pilot is being used at an exact moment in the 100% threshold that would trigger

project at Kindersley aimed at maintaining time. This helps predict how much additional electrical usage and costs.

usage below peak demand using each individual motor contributes to

recommendations including: the overall power total.

Once the pilot is complete, the results will be reviewed to determine if the project can be expanded to other facilities in the future

to make our electrical usage more efficient.

Marine unloading tower upgrade

At our port facility in Montreal, we are currently two-thirds of the way through a significant, multi-

year upgrade of our marine unloading towers. The goal of this project is to ensure the continued

safe and efficient operation of the towers, while bringing our control equipment up to modern

standards. This includes making several automation improvements.

The first two towers have been completed, with the third and final tower scheduled for completion

this winter. Thank you to our team members involved in the successful planning and execution of

this project so far.

Infographic: Economic impact of wheat and durum in Canada

| 5