Page 9 - QR CIMAR PADDLE MIXER

P. 9

4. Thoroughly clean the Cement Mixer at the end of each day’s operation. The Drum (55) may be scoured for

approximately two minutes, using a gravel and water mixture. Then discharge the gravel/water mixture and

hose down the Drum inside and out.

5. Dried cement mix should be scraped out of the Drum (55). Do not beat on the Drum with a shovel or other

tools to break up accumulations of dried cement mix, as damage to the Cement Mixer may result.

6. Do not pour water over the Engine (34). Refer to the Engine manufacturer’s instruction manual for all

inspection, maintenance, and cleaning procedures.

7. Periodically, lubricate all moving parts of the Cement Mixer.

8. IMPORTANT: Whenever a Hub (7) is disassembled for maintenance the following procedure MUST be

followed: NOTE: A bearing packer (not included) must be used for this procedure.

a. Using a suitable solvent, thoroughly clean the Bearing (7), Oil Seal (10), Castle Nut (12), Cotter Pin (13),

and the rest of the parts of the Hub assembly of all old grease, dirt, metal shavings, and any other

foreign materials. The parts must be cleaned, even if they are new or appear clean.

b. Allow the parts to dry completely.

c. Make sure your hands are clean and the bearing packer (not included) is also clean.

d. Place fresh grease in the bearing packer.

e. With the grease-filled bearing packer in one hand and the Bearing (11) in the other, press the Bearing

into the grease, forcing the grease inside the slots in the Bearing. Continue doing this until every slot in

the Bearing is completely full of grease.

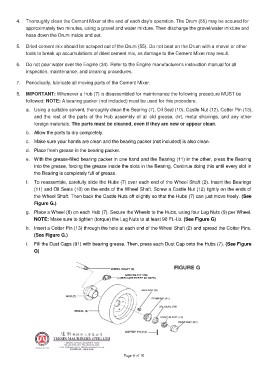

f. To reassemble, carefully slide the Hubs (7) over each end of the Wheel Shaft (2). Insert the Bearings

(11) and Oil Seals (10) on the ends of the Wheel Shaft. Screw a Castle Nut (12) tightly on the ends of

the Wheel Shaft. Then back the Castle Nuts off slightly so that the Hubs (7) can just move freely. (See

Figure G.)

g. Place a Wheel (8) on each Hub (7). Secure the Wheels to the Hubs, using four Lug Nuts (9) per Wheel.

NOTE: Make sure to tighten (torque) the Lug Nuts to at least 90 Ft.-Lb. (See Figure G)

h. Insert a Cotter Pin (13) through the hole at each end of the Wheel Shaft (2) and spread the Cotter Pins.

(See Figure G.)

i. Fill the Dust Caps (91) with bearing grease. Then, press each Dust Cap onto the Hubs (7). (See Figure

G)

Page 8 of 10