Page 79 - ITALVIBRAS E-CATALOG

P. 79

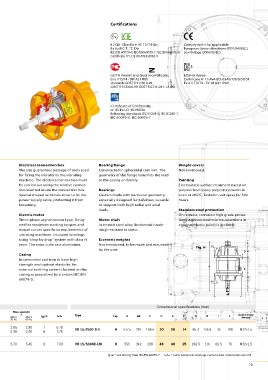

Certifications

II 2 GD - Class Ex e IIC T3/T4 Gb, Comply with the applicable

Ex tb IIIC T...°C Db European Union directives: ATEX (94/9/EC),

Low Voltage (2006/95/EC).

IEC/EN 60079-0, IEC/EN 60079-7, IEC/EN 60079-31

Certificate n° LCIE 06 ATEX 6092 X

N

GGTN Permit and Gost-R certificate: KOSHA Korea

Ex e II T3/T4 - DIP A21 IP66 Certificate n° 11-AV4 BO-0346/7/8/9/50/51

standards GOST R 51330.0-99, Ex e II T3/T4 - Ex td A21 IP66

GOST R 51330.8-99, GOST R IEC 61241-1-1-99.

Certificate of Conformity

n° IECEx LCI 10.0003X

following standards IEC 61241-0, IEC 61241-1,

IEC 60079-0, IEC 60079-7

Electrical connection box Bearing flange Weight covers

The size guarantees passage of tools used Constructed in spheroidal cast iron. The Not envisioned.

for fixing the vibrator to the vibrating geometry of the flange transmits the load

machine. The electrical connection must to the casing uniformly. Painting

be carried out using the relative connec- Electrostatic surface treatment based on

tors inserted inside the connection box. Bearings polymerised epoxy polyester powder in

Special shaped terminals allow to fix the Custom made with particular geometry, oven at 200°C. Tested in salt spray for 500

power supply cable, protecting it from especially designed for Italvibras, suitable hours.

loosening. to support both high radial and axial

loads. Stainless steel protection

Electric motor On request, corrosion high grade protec-

Three-phase asynchronous type. Desig- Motor shaft tion (stainless steel micro suspensions in

ned for maximum starting torques and In treated steel alloy (Isothermic harde- a polyurethanic paint) is available.

torque curves specific to requirements of ning) resistant to stress.

vibrating machines. Insulated windings Fig. H

using “drop by drop” system with class H Eccentric weights

resin. The rotor is die cast aluminium. Not envisioned, to be made and mounted

by the user.

Casing

In spheroidal cast iron to have high

strength and optimal elasticity. An

external earthing screw is located on the

casing as prescribed by standard IEC/EN

60079-0.

Max. current Dimensional specifications (mm)

A Cable entry

400 V 460 V tE (s) IA/lN Type Fig. A øB C D E F° G H I L thread

VB 15/2510-D-E

50 Hz 60 Hz 7 6.70

6 7.76

2.85 2.80 H 517.5 281 158.5 30 26 14 85.3 136.6 35 108 M32x1.5

2.38 2.30

5.70 5.45 6 7.00 VB 15/5000E-LM H 555 342 208 48 48 25 106.5 110 60.5 70 M32x1,5

tE (s) = set time tE from IEC/EN 60079-7. IA/lN = ratio between start-up current and maximum current.

79