Page 23 - ProposalBookletLakelandRegMedCenterMOB

P. 23

Chapter IV, Construc on Plan

Chapter IV, Construc on Plan

CONSTRUCTION PROCESS

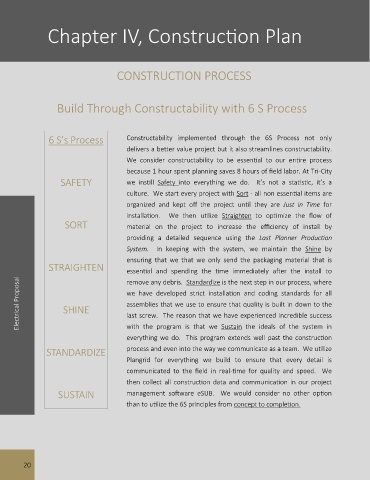

Build Through Constructability with 6 S Process

6 S’s Process Constructability implemented through the 6S Process not only

delivers a beKer value project but it also streamlines constructability.

We consider constructability to be essen al to our en re process

because 1 hour spent planning saves 8 hours of field labor. At Tri-City

SAFETY we ins ll Safety into everything we do. It’s not a sta s c, it’s a

culture. We start every project with Sort - all non essen al items are

organized and kept off the project un l they are Just in Time for

installa on. We then u lize Straighten to op mize the flow of

SORT material on the project to increase the efficiency of install by

providing a detailed sequence using the Last Planner Produc0on

System. In keeping with the system, we maintain the Shine by

ensuring that we that we only send the packaging material that is

STRAIGHTEN essen al and spending the me immediately aLer the install to

Electrical Proposal SHINE we have developed strict installa on and coding standards for all

remove any debris. Standardize is the next step in our process, where

assemblies that we use to ensure that quality is built in down to the

last screw. The reason that we have experienced incredible success

with the program is that we Sustain the ideals of the system in

everything we do. This program extends well past the construc on

STANDARDIZE process and even into the way we communicate as a team. We u lize

Plangrid for everything we build to ensure that every detail is

communicated to the field in real- me for quality and speed. We

then collect all construc on data and communica on in our project

SUSTAIN management soLware eSUB. We would consider no other op on

than to u lize the 6S principles from concept to comple on.

20