Page 39 - SSAB Welding Handbook Edition 2

P. 39

©2009-2019 by SSAB Group of companies (SSAB). All rights reserved. Only digital PDF file. No distribution. No printing allowed!

No part of this handbook may be reproduced in any form or by any means without permission in writing from SSAB.

Welding handbook 6.0 The choice of consumables

6.0 The choice of consumables

©SSAB

The Hardox and Strenx grades are normally 6.2 The static strengths of the

welded with unalloyed and low-alloyed consumables. consumables

Stainless austenitic consumables can be even more

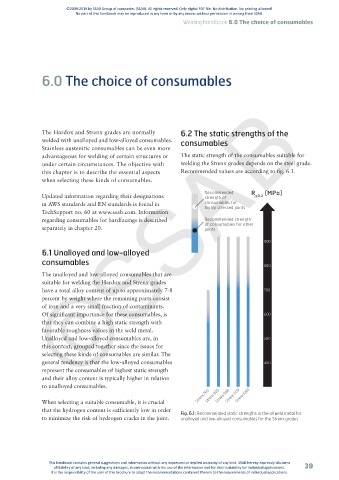

advantageous for welding of certain structures or The static strength of the consumables suitable for

under certain circumstances. The objective with welding the Strenx grades depends on the steel grade.

this chapter is to describe the essential aspects Recommended values are according to fig. 6.1.

when selecting these kinds of consumables.

Recommended R [MPa]

Updated information regarding their designations strength of p0.2

in AWS standards and EN standards is found in consumables for

highly stressed joints

TechSupport no. 60 at www.ssab.com. Information

regarding consumables for hardfacings is described Recommended strength

of consumables for other MMA

separately in chapter 20. joints

900

EN 757

6.1 Unalloyed and low-alloyed

consumables 800

EN 757

The unalloyed and low-alloyed consumables that are

suitable for welding the Hardox and Strenx grades

have a total alloy content of up to approximately 7-8 700

EN 757

percent by weight where the remaining parts consist

of iron and a very small fraction of contaminants. EN 757

Of significant importance for these consumables, is 600

that they can combine a high static strength with

favorable toughness values in the weld metal. EN 757

Unalloyed and low-alloyed consumables are, in 500 EN ISO 2560(-A)

this context, grouped together since the issues for

selecting these kinds of consumables are similar. The EN ISO 2560(-A)

EN ISO 2560(-A)

general tendency is that the low-alloyed consumables 400

represent the consumables of highest static strength

and their alloy content is typically higher in relation

to unalloyed consumables.

Strenx 700 Strenx 900 Strenx 960 Strenx 1100 Strenx 1300

When selecting a suitable consumable, it is crucial

that the hydrogen content is sufficiently low in order

Fig. 6.1: Recommended static strengths in the all weld metal for

to minimize the risk of hydrogen cracks in the joint. unalloyed and low-alloyed consumables for the Strenx grades.

This handbook contains general suggestions and information without any expressed or implied warranty of any kind. SSAB hereby expressly disclaims

all liability of any kind, including any damages, in connection with the use of the information and for their suitability for individual applications. 39

It is the responsibility of the user of this brochure to adapt the recommendations contained therein to the requirements of individual applications.