Page 18 - BULETIN GEOTEKNIK 2023

P. 18

Maintain

Static

Load Test

Maintain static load test (MLT) is the most

common and reliable pile testing method used

in the construction industry. This method is

commonly used to determine the load carry

capacity of a pile without excessive

settlement. Pile behaviour or it’s resulting

displacement under the applied load i.e. the

design load for a longer period is also the key

point which a geotechnical engineer would

like to investigate by using this maintain static

load test method. Schematic arrangement of

this test is shown in Figure 2.

However, maintain load test has a list of

disadvantages such as taking longer time to

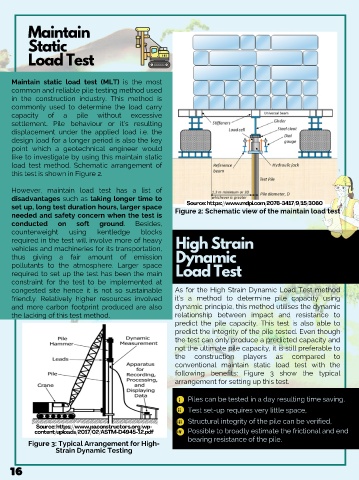

Source: https://www.mdpi.com/2076-3417/9/15/3060

set up, long test duration hours, larger space Figure 2: Schematic view of the maintain load test

needed and safety concern when the test is

conducted on soft ground. Besides,

counterweight using kentledge blocks

required in the test will involve more of heavy High Strain

vehicles and machineries for its transportation,

thus giving a fair amount of emission Dynamic

pollutants to the atmosphere. Larger space

required to set up the test has been the main Load Test

constraint for the test to be implemented at

congested site hence it is not so sustainable As for the High Strain Dynamic Load Test method

friendly. Relatively higher resources involved it’s a method to determine pile capacity using

and more carbon footprint produced are also dynamic principle, this method utilises the dynamic

the lacking of this test method. relationship between impact and resistance to

predict the pile capacity. This test is also able to

predict the integrity of the pile tested. Even though

the test can only produce a predicted capacity and

not the ultimate pile capacity, it is still preferable to

the construction players as compared to

conventional maintain static load test with the

following benefits: Figure 3 show the typical

arrangement for setting up this test.

i Piles can be tested in a day resulting time saving,

ii Test set-up requires very little space,

iii Structural integrity of the pile can be verified,

Source: https://www.paconstructors.org/wp-

content/uploads/2017/02/ASTM-D4945-12.pdf iv Possible to broadly estimate the frictional and end

bearing resistance of the pile.

Figure 3: Typical Arrangement for High-

Strain Dynamic Testing

16