Page 15 - June 2020 Newsletter

P. 15

June Return to

2020 `Triumphs Live On’ Start

Page 14

www.tswf

l.org

Tech Corner-continued

In all instances, the key component is the use of a charcoal canister to trap gas fumes from the gas tank and the carburetor

float bowls. The trapped fumes are then sucked through the valve cover, through the crankcase and out the vent on the

tappet cover on the side of the engine by carb vacuum. This system uses absolutely no energy to operate so it should be

left functional when you remove the air pump and other emission equipment. Over time, the filters and charcoal degrade

to the point of being sucked into the crankcase. One thing you do not want in your crankcase is bits of charcoal.

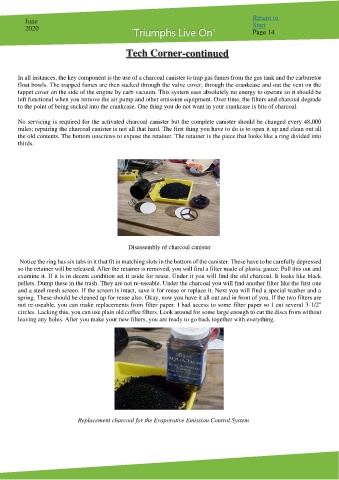

No servicing is required for the activated charcoal canister but the complete canister should be changed every 48,000

miles; repairing the charcoal canister is not all that hard. The first thing you have to do is to open it up and clean out all

the old contents. The bottom unscrews to expose the retainer. The retainer is the piece that looks like a ring divided into

thirds.

Disassembly of charcoal canister

Notice the ring has six tabs in it that fit in matching slots in the bottom of the canister. These have to be carefully depressed

so the retainer will be released. After the retainer is removed, you will find a filter made of plastic gauze. Pull this out and

examine it. If it is in decent condition set it aside for reuse. Under it you will find the old charcoal. It looks like black

pellets. Dump these in the trash. They are not re-useable. Under the charcoal you will find another filter like the first one

and a steel mesh screen. If the screen is intact, save it for reuse or replace it. Next you will find a special washer and a

spring. These should be cleaned up for reuse also. Okay, now you have it all out and in front of you. If the two filters are

not re-useable, you can make replacements from filter paper. I had access to some filter paper so I cut several 3-1/2"

circles. Lacking this, you can use plain old coffee filters. Look around for some large enough to cut the discs from without

leaving any holes. After you make your new filters, you are ready to go back together with everything.

Replacement charcoal for the Evaporative Emission Control System