Page 5 - August2020

P. 5

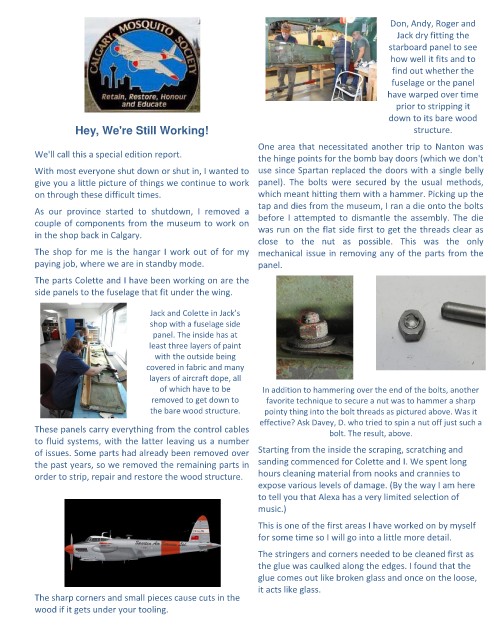

Don, Andy, Roger and

Jack dry fitting the

starboard panel to see

how well it fits and to

find out whether the

fuselage or the panel

have warped over time

prior to stripping it

down to its bare wood

Hey, We're Still Working! structure.

One area that necessitated another trip to Nanton was

We'll call this a special edition report.

the hinge points for the bomb bay doors (which we don't

With most everyone shut down or shut in, I wanted to use since Spartan replaced the doors with a single belly

give you a little picture of things we continue to work panel). The bolts were secured by the usual methods,

on through these difficult times. which meant hitting them with a hammer. Picking up the

tap and dies from the museum, I ran a die onto the bolts

As our province started to shutdown, I removed a

before I attempted to dismantle the assembly. The die

couple of components from the museum to work on

was run on the flat side first to get the threads clear as

in the shop back in Calgary.

close to the nut as possible. This was the only

The shop for me is the hangar I work out of for my mechanical issue in removing any of the parts from the

paying job, where we are in standby mode. panel.

The parts Colette and I have been working on are the

side panels to the fuselage that fit under the wing.

Jack and Colette in Jack’s

shop with a fuselage side

panel. The inside has at

least three layers of paint

with the outside being

covered in fabric and many

layers of aircraft dope, all

of which have to be In addition to hammering over the end of the bolts, another

removed to get down to favorite technique to secure a nut was to hammer a sharp

the bare wood structure. pointy thing into the bolt threads as pictured above. Was it

effective? Ask Davey, D. who tried to spin a nut off just such a

These panels carry everything from the control cables

bolt. The result, above.

to fluid systems, with the latter leaving us a number

of issues. Some parts had already been removed over Starting from the inside the scraping, scratching and

the past years, so we removed the remaining parts in sanding commenced for Colette and I. We spent long

order to strip, repair and restore the wood structure. hours cleaning material from nooks and crannies to

expose various levels of damage. (By the way I am here

to tell you that Alexa has a very limited selection of

music.)

This is one of the first areas I have worked on by myself

for some time so I will go into a little more detail.

The stringers and corners needed to be cleaned first as

the glue was caulked along the edges. I found that the

glue comes out like broken glass and once on the loose,

it acts like glass.

The sharp corners and small pieces cause cuts in the

wood if it gets under your tooling.