Page 8 - August2020

P. 8

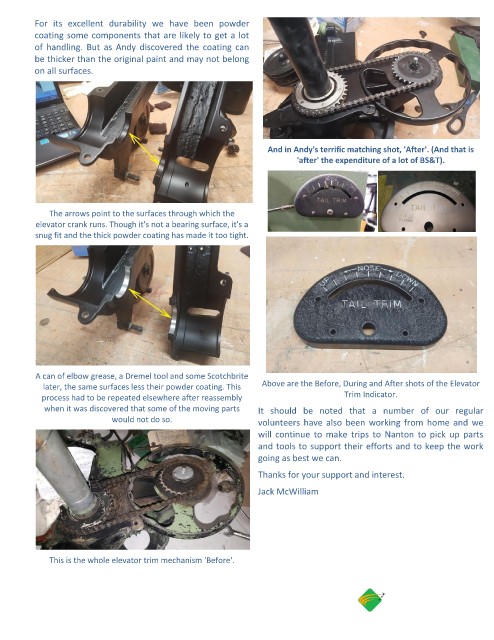

For its excellent durability we have been powder

coating some components that are likely to get a lot

of handling. But as Andy discovered the coating can

be thicker than the original paint and may not belong

on all surfaces.

And in Andy's terrific matching shot, 'After'. (And that is

'after' the expenditure of a lot of BS&T).

The arrows point to the surfaces through which the

elevator crank runs. Though it's not a bearing surface, it's a

snug fit and the thick powder coating has made it too tight.

A can of elbow grease, a Dremel tool and some Scotchbrite

later, the same surfaces less their powder coating. This Above are the Before, During and After shots of the Elevator

process had to be repeated elsewhere after reassembly Trim Indicator.

when it was discovered that some of the moving parts It should be noted that a number of our regular

would not do so.

volunteers have also been working from home and we

will continue to make trips to Nanton to pick up parts

and tools to support their efforts and to keep the work

going as best we can.

Thanks for your support and interest.

Jack McWilliam

This is the whole elevator trim mechanism 'Before'.