Page 16 - Gi August 2020

P. 16

PIPELINES FOR A

HYDROGEN FUTURE

Andrew Stevenson, Doug Everard and Mebs Bobat, of as a result of internal and external

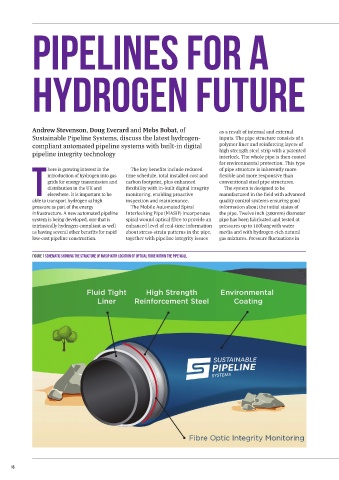

Sustainable Pipeline Systems, discuss the latest hydrogen- inputs. The pipe structure consists of a

compliant automated pipeline systems with built-in digital polymer liner and reinforcing layers of

pipeline integrity technology high strength steel strip with a patented

interlock. The whole pipe is then coated

for environmental protection. This type

here is growing interest in the The key benefits include reduced of pipe structure is inherently more

introduction of hydrogen into gas time schedule, total installed cost and flexible and more responsive than

grids for energy transmission and carbon footprint, plus enhanced conventional steel pipe structures.

distribution in the UK and flexibility with in-built digital integrity The system is designed to be

T elsewhere. It is important to be monitoring, enabling proactive manufactured in the field with advanced

able to transport hydrogen at high inspection and maintenance. quality control systems ensuring good

pressure as part of the energy The Mobile Automated Spiral information about the initial status of

infrastructure. A new automated pipeline Interlocking Pipe (MASiP) incorporates the pipe. Twelve inch (300mm) diameter

system is being developed, one that is spiral wound optical fibre to provide an pipe has been fabricated and tested at

intrinsically hydrogen-compliant as well enhanced level of real-time information pressures up to 100barg with water

as having several other benefits for rapid about stress-strain patterns in the pipe, media and with hydrogen-rich natural

low-cost pipeline construction. together with pipeline integrity issues gas mixtures. Pressure fluctuations in

FIGURE 1 SCHEMATIC SHOWING THE STRUCTURE OF MASIP WITH LOCATION OF OPTICAL FIBRE WITHIN THE PIPE WALL

16

16/07/2020 11:50

DigitalPipeline.indd 1 16/07/2020 11:50

DigitalPipeline.indd 1