Page 39 - Gi flipbook April 2019

P. 39

DeSIGN STANDARDS & BeNeFITS

The method of supporting the ball in a trunnion mounted ball

valve is of little importance in cases when the valve is small and

the pressures are low. However, the forces generated in a large

valve closed against high pressure are enormous and they create

2500

a major challenge for the valve designer. The magnitude of the

stresses and deflections generated by these forces depend upon

the design employed for supporting the ball. If stresses are too

2000

high some form of valve failure will occur, either initially or at some

time during service. If deflections are excessive, then the valve

1500

operating torque will be too high and the bearings may be unevenly

loaded resulting in premature failure.

1000

In some designs of trunnion mounted ball valves, trunnions project

from inside the valve body into sockets in the ball. These trunnions

are therefore subjected to a couple which could be massive and TON F 1500 600 900 300 150

500

result in unacceptable deflections together with high stress levels in

the valve body which is already subject to pressure forces. In other

designs, the valve stem is used as a trunnion which creates the 6” 12” 18” 24” 30” 36” 42” 48”

additional problem of possible stem leaks due to the application of

side loads to the stem seals. NOMINAL VALVE SIZE igem news – yppc

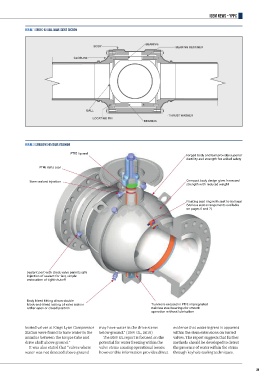

FIGURE 1 CORT C-B5 BALL VALVE CROSS SECTION

FEATURES AND BENEFITS

As one of the most trusted valves in the petroleum Engineered for heavy-duty, maintenance-free performance,

BeARING

BODY BeARING ReTAINeR

industry, the CAMERON fully welded ball valve combines the CAMERON fully welded ball valve is commonly

the strength of forged components with a lightweight selected for a number of applications, including:

ClOSURe

and compact spherical design. • Gas transmission • NGL plants

CAMERON fully welded ball valves satisfy ASME/ANSI • Product pipeline s • NGL pipeline

150 to 2500 (PN 20 to PN 420) and API 2000 to 5000 • Measurement skids • Compressor stations

standards. Made of forged steel to ensure uniform fine • Dehydration systems • CO services

2

grain structure and toughness, they can be specified in • Gas separation systems • Offshore

sizes from 2” to 56” (50 mm to 1400 mm).

• Natural gas storage • Subsea

BAll

• Dryer service

ThRUST WASheR

lOCATING PIN

BeARING

The distinctive design of the CAMERON fully welded ball valve gives it strength at reduced weight, as well as resistance to

both pipeline pressures and stresses. The compact, spherical design also eliminates body flanges, reducing overall size and

potential leak paths.

The design used in the CORT C-B5 for supporting the ball is not

FIGURE 2 CAMERON C-B5 VALVE OVERVIEW closures via the bearing retainers, which are put into compression.

the lowest cost but it is the most elegant and effective engineering The result is that for practical purposes, bending is eliminated from

solution. Both trunnions and the ball are a single component, thus these components and the deflections produced are minimal.

PTFE lip seal

Forged body and ball provides superior

eliminating the problems associated with a highly stressed joint. Mating surfaces remain square and parallel to each other so

ductility and strength for added safety

The trunnions are as close together as possible (normally within that stress distributions are uniform and stress levels remain

the ball spherical diameter) ensuring that the bending moment low. The stem is not rigidly attached to the upper trunnion and

PTFE delta seal

is minimised and applied to only the stiffest part of the ball. The therefore, although it can apply torsion to the ball, no side thrust is

trunnions are short in relation to their diameter and primarily transmitted from the ball onto the stem seals.

subject only to shear stress. The force is transmitted into the valve Compact body design gives increased

Stem sealant injection

strength with reduced weight

3 Valves and Through-Life Asset Management

Floating seat ring with seat to ball seal

(Various seat arrangements available

on pages 6 and 7)

Sealant port with check valve permits safe

injection of sealant for fast, simple

restoration of tight shutoff

Body bleed fitting allows double

block-and-bleed testing of valve seals in Trunnions encased in PTFE impregnated

either open or closed position stainless steel bearings for smooth

operation without lubrication

buried valves at Kings Lynn Compressor may have water in the drive stems evidence that water ingress is apparent 3

Station were found to have water in the below ground.” (DNV GL, 2016) within the stem extensions on buried

annulus between the torque tube and The DNV GL report is focused on the valves. The report suggests that further

drive shaft above ground.” potential for water freezing within the methods should be developed to detect

It was also stated that “valves where valve stems causing operational issues; the presence of water within the stems

water was not detected above ground however this information provides direct through keyhole tooling techniques.

39

IGEMNews_YPPC.indd 2 14/03/2019 14:23