Page 24 - Gi_May2020

P. 24

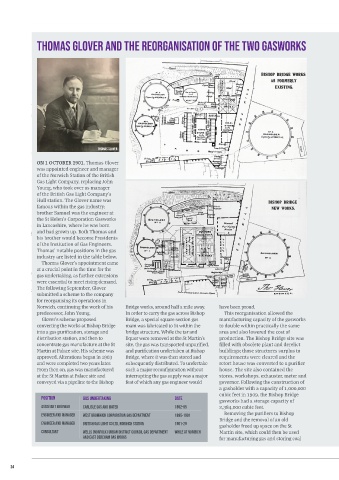

THOMAS GLOVER AND THE REORGANISATION OF THE TWO GASWORKS

THOMAS GLOVER

ON 1 OCTOBER 1901, Thomas Glover

was appointed engineer and manager

of the Norwich Station of the British

Gas Light Company, replacing John

Young, who took over as manager

of the British Gas Light Company’s

Hull station. The Glover name was

famous within the gas industry;

brother Samuel was the engineer at

the St Helen’s Corporation Gasworks

in Lancashire, where he was born

and had grown up. Both Thomas and

his brother would become Presidents

of the Institution of Gas Engineers.

Thomas’ notable positions in the gas

industry are listed in the table below.

Thomas Glover’s appointment came

at a crucial point in the time for the

gas undertaking, as further extensions

were essential to meet rising demand.

The following September, Glover

submitted a scheme to the company

for reorganising its operations in

Norwich, continuing the work of his Bridge works, around half a mile away. have been proud.

predecessor, John Young. In order to carry the gas across Bishop This reorganisation allowed the

Glover’s scheme proposed Bridge, a special square section gas manufacturing capacity of the gasworks

converting the works at Bishop Bridge main was fabricated to fit within the to double within practically the same

into a gas purification, storage and bridge structure. While the tar and area and also lowered the cost of

distribution station, and then to liquor were removed at the St Martin’s production. The Bishop Bridge site was

concentrate gas manufacture at the St site, the gas was transported unpurified, filled with obsolete plant and derelict

Martin at Palace site. His scheme was and purification undertaken at Bishop buildings; those structures surplus to

approved. Alterations began in 1903 Bridge, where it was then stored and requirements were cleared and the

and were completed two years later. subsequently distributed. To undertake retort house was converted to a purifier

From then on, gas was manufactured such a major reconfiguration without house. The site also contained the

at the St Martin at Palace site and interrupting the gas supply was a major stores, workshops, exhauster, meter and

conveyed via a pipeline to the Bishop feat of which any gas engineer would governor. Following the construction of

a gasholder with a capacity of 1,000,000

cubic feet in 1909, the Bishop Bridge

POSITION GAS UNDERTAKING DATE gasworks had a storage capacity of

ASSISTANT ENGINEER CARLISLE GAS AND WATER 1892-95 2,384,000 cubic feet.

ENGINEER AND MANAGER WEST BROMWICH CORPORATION GAS DEPARTMENT 1895-1901 Removing the purifiers to Bishop

Bridge and the removal of an old

ENGINEER AND MANAGER BRITISH GAS LIGHT CO LTD, NORWICH STATION 1901-29 gasholder freed up space on the St

CONSULTANT WELLS (NORFOLK) URBAN DISTRICT COUNCIL GAS DEPARTMENT WHILE AT NORWICH Martin site, which could then be used

AND EAST DEREHAM GAS WORKS for manufacturing gas and storing coal

24

16/04/2020 13:58

HistoryOfGas.indd 3

HistoryOfGas.indd 3 16/04/2020 13:58