Page 4 - BROCHURE 2

P. 4

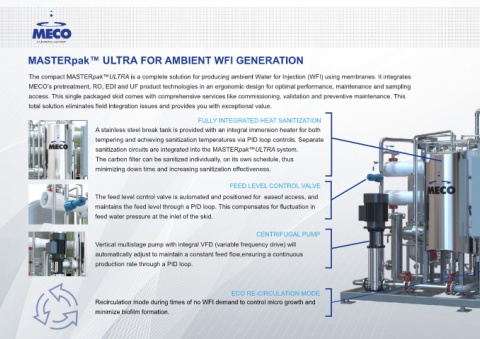

MASTERpak™ ULTRA FOR AMBIENT WFI GENERATION

The compact MASTERpak™ULTRA is a complete solution for producing ambient Water for Injection (WFI) using membranes. It integrates

MECO’s pretreatment, RO, EDI and UF product technologies in an ergonomic design for optimal performance, maintenance and sampling

access. This single packaged skid comes with comprehensive services like commissioning, validation and preventive maintenance. This

total solution eliminates field integration issues and provides you with exceptional value.

FULLY INTEGRATED HEAT SANITIZATION

A stainless steel break tank is provided with an integral immersion heater for both

tempering and achieving sanitization temperatures via PID loop controls. Separate QUIETER OPERATION

sanitization circuits are integrated into the MASTERpak™ULTRA system. Operating at only 72 – 85 dBA, MECO's GII Centurbo™ Compressor is quiet.

The carbon filter can be sanitized individually, on its own schedule, thus You don't need acoustic walls or personal hearing protection. Because people

in adjoining spaces aren't affected, you can position your water room just about

minimizing down time and increasing sanitization effectiveness.

anywhere, even right next to an office. Your water room works better and is

FEED LEVEL CONTROL VALVE a better place to work.

The feed level control valve is automated and positioned for easeof access, and

maintains the feed level through a PID loop. This compensates for fluctuation in

feed water pressure at the inlet of the skid.

WATER QUALITY

Non-condensable gasses, such as CO2 and oxygen, if allowed into the evaporator,

CENTRIFUGAL PUMP

cause corrosion and blanket heat transfer surfaces, which reduces output and can

Vertical multistage pump with integral VFD (variable frequency drive) will contribute to higher conductivity. The feed water deaerator strips most non-condensable

automatically adjust to maintain a constant feed flow,ensuring a continuous gasses prior to entry into the evaporator, thus maximizing efficiency and minimizing corrosion.

production rate through a PID loop.

WATER QUALITY

ECO RE-CIRCULATION MODE

Recirculation mode during times of no WFI demand to control micro growth and Non-condensable gasses, such as CO2 and oxygen, if allowed into the evaporator,

cause corrosion and blanket heat transfer surfaces, which reduces output and can

minimize biofilm formation.

contribute to higher conductivity. The feed water deaerator strips most non-condensable

gasses prior to entry into the evaporator, thus maximizing efficiency and minimizing corrosion.

WATER QUALITY

Non-condensable gasses, such as CO2 and oxygen, if allowed into the evaporator,

cause corrosion and blanket heat transfer surfaces, which reduces output and can

contribute to higher conductivity. The feed water deaerator strips most non-condensable

gasses prior to entry into the evaporator, thus maximizing efficiency and minimizing corrosion.