Page 7 - BROCHURE 2

P. 7

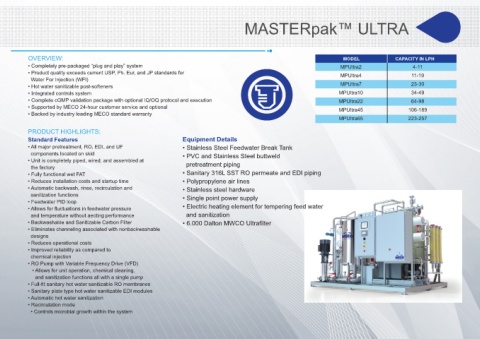

MASTERpak™ ULTRA

OVERVIEW: MODEL CAPACITY IN LPH

• Completely pre-packaged “plug and play” system MPUltra2 4-11

• Product quality exceeds current USP, Ph. Eur, and JP standards for

MPUltra4 11-19

Water For Injection (WFI)

MPUltra7 23-30

• Hot water sanitizable post-softeners

• Integrated controls system MPUltra10 34-49

• Complete cGMP validation package with optional IQ/OQ protocol and execution MPUltra22 64-98

• Supported by MECO 24-hour customer service and optional

MPUltra45 106-189

• Backed by industry leading MECO standard warranty

MPUltra65 223-257

PRODUCT HIGHLIGHTS:

Standard Features Equipment Details

• All major pretreatment, RO, EDI, and UF • Stainless Steel Feedwater Break Tank

components located on skid • PVC and Stainless Steel buttweld

• Unit is completely piped, wired, and assembled at

the factory pretreatment piping

• Fully functional wet FAT • Sanitary 316L SST RO permeate and EDI piping

• Reduces installation costs and startup time • Polypropylene air lines

• Automatic backwash, rinse, recirculation and • Stainless steel hardware

sanitization functions

• Single point power supply

• Feedwater PID loop

• Electric heating element for tempering feed water

• Allows for fluctuations in feedwater pressure

and temperature without aecting performance and sanitization

• Backwashable and Sanitizable Carbon Filter • 6.000 Dalton MWCO Ultrafilter

• Eliminates channeling associated with nonbackwashable

designs

• Reduces operational costs

• Improved reliability as compared to

chemical injection

• RO Pump with Variable Frequency Drive (VFD)

• Allows for unit operation, chemical cleaning,

and sanitization functions all with a single pump

• Full-fit sanitary hot water sanitizable RO membranes

• Sanitary plate type hot water sanitizable EDI modules

• Automatic hot water sanitization

• Recirculation mode

• Controls microbial growth within the system