Page 115 - Training 2019

P. 115

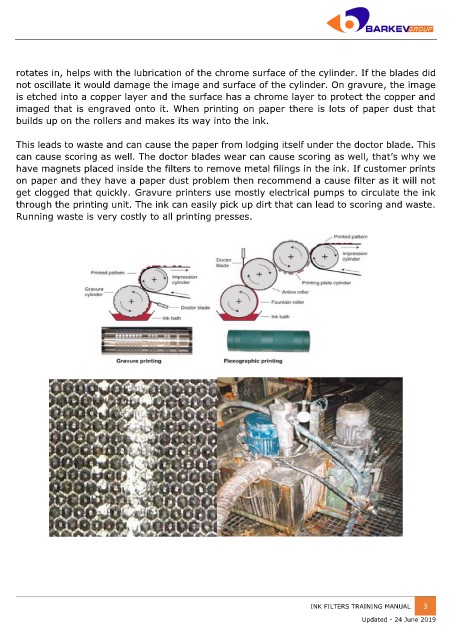

rotates in, helps with the lubrication of the chrome surface of the cylinder. If the blades did

not oscillate it would damage the image and surface of the cylinder. On gravure, the image

is etched into a copper layer and the surface has a chrome layer to protect the copper and

imaged that is engraved onto it. When printing on paper there is lots of paper dust that

builds up on the rollers and makes its way into the ink.

This leads to waste and can cause the paper from lodging itself under the doctor blade. This

can cause scoring as well. The doctor blades wear can cause scoring as well, that’s why we

have magnets placed inside the filters to remove metal filings in the ink. If customer prints

on paper and they have a paper dust problem then recommend a cause filter as it will not

get clogged that quickly. Gravure printers use mostly electrical pumps to circulate the ink

through the printing unit. The ink can easily pick up dirt that can lead to scoring and waste.

Running waste is very costly to all printing presses.

INK FILTERS TRAINING MANUAL 3

Updated - 24 June 2019