Page 220 - Training 2019

P. 220

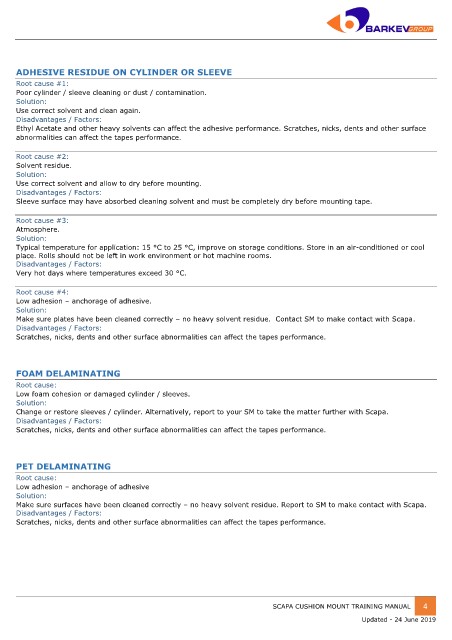

ADHESIVE RESIDUE ON CYLINDER OR SLEEVE

Root cause #1:

Poor cylinder / sleeve cleaning or dust / contamination.

Solution:

Use correct solvent and clean again.

Disadvantages / Factors:

Ethyl Acetate and other heavy solvents can affect the adhesive performance. Scratches, nicks, dents and other surface

abnormalities can affect the tapes performance.

Root cause #2:

Solvent residue.

Solution:

Use correct solvent and allow to dry before mounting.

Disadvantages / Factors:

Sleeve surface may have absorbed cleaning solvent and must be completely dry before mounting tape.

Root cause #3:

Atmosphere.

Solution:

Typical temperature for application: 15 °C to 25 °C, improve on storage conditions. Store in an air-conditioned or cool

place. Rolls should not be left in work environment or hot machine rooms.

Disadvantages / Factors:

Very hot days where temperatures exceed 30 °C.

Root cause #4:

Low adhesion – anchorage of adhesive.

Solution:

Make sure plates have been cleaned correctly – no heavy solvent residue. Contact SM to make contact with Scapa.

Disadvantages / Factors:

Scratches, nicks, dents and other surface abnormalities can affect the tapes performance.

FOAM DELAMINATING

Root cause:

Low foam cohesion or damaged cylinder / sleeves.

Solution:

Change or restore sleeves / cylinder. Alternatively, report to your SM to take the matter further with Scapa.

Disadvantages / Factors:

Scratches, nicks, dents and other surface abnormalities can affect the tapes performance.

PET DELAMINATING

Root cause:

Low adhesion – anchorage of adhesive

Solution:

Make sure surfaces have been cleaned correctly – no heavy solvent residue. Report to SM to make contact with Scapa.

Disadvantages / Factors:

Scratches, nicks, dents and other surface abnormalities can affect the tapes performance.

SCAPA CUSHION MOUNT TRAINING MANUAL 4

Updated - 24 June 2019