Page 218 - Training 2019

P. 218

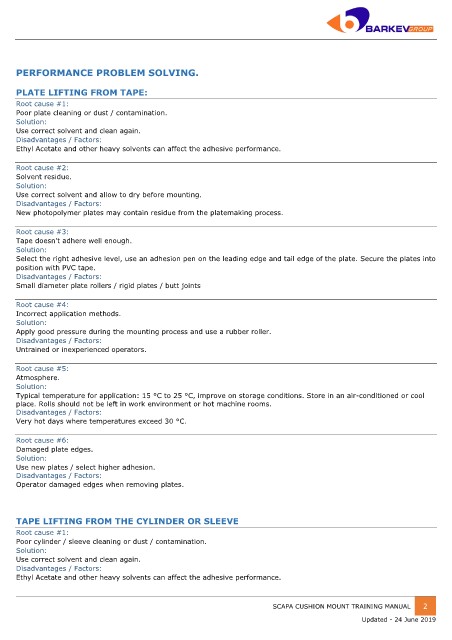

PERFORMANCE PROBLEM SOLVING.

PLATE LIFTING FROM TAPE:

Root cause #1:

Poor plate cleaning or dust / contamination.

Solution:

Use correct solvent and clean again.

Disadvantages / Factors:

Ethyl Acetate and other heavy solvents can affect the adhesive performance.

Root cause #2:

Solvent residue.

Solution:

Use correct solvent and allow to dry before mounting.

Disadvantages / Factors:

New photopolymer plates may contain residue from the platemaking process.

Root cause #3:

Tape doesn’t adhere well enough.

Solution:

Select the right adhesive level, use an adhesion pen on the leading edge and tail edge of the plate. Secure the plates into

position with PVC tape.

Disadvantages / Factors:

Small diameter plate rollers / rigid plates / butt joints

Root cause #4:

Incorrect application methods.

Solution:

Apply good pressure during the mounting process and use a rubber roller.

Disadvantages / Factors:

Untrained or inexperienced operators.

Root cause #5:

Atmosphere.

Solution:

Typical temperature for application: 15 °C to 25 °C, improve on storage conditions. Store in an air-conditioned or cool

place. Rolls should not be left in work environment or hot machine rooms.

Disadvantages / Factors:

Very hot days where temperatures exceed 30 °C.

Root cause #6:

Damaged plate edges.

Solution:

Use new plates / select higher adhesion.

Disadvantages / Factors:

Operator damaged edges when removing plates.

TAPE LIFTING FROM THE CYLINDER OR SLEEVE

Root cause #1:

Poor cylinder / sleeve cleaning or dust / contamination.

Solution:

Use correct solvent and clean again.

Disadvantages / Factors:

Ethyl Acetate and other heavy solvents can affect the adhesive performance.

SCAPA CUSHION MOUNT TRAINING MANUAL 2

Updated - 24 June 2019