Page 214 - Training 2019

P. 214

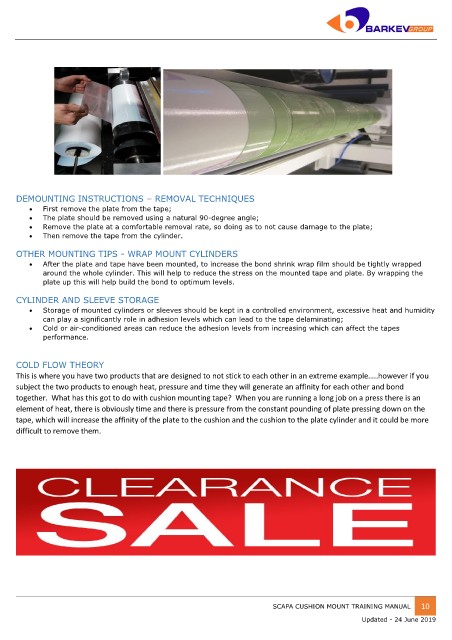

DEMOUNTING INSTRUCTIONS – REMOVAL TECHNIQUES

First remove the plate from the tape;

The plate should be removed using a natural 90-degree angle;

Remove the plate at a comfortable removal rate, so doing as to not cause damage to the plate;

Then remove the tape from the cylinder.

OTHER MOUNTING TIPS - WRAP MOUNT CYLINDERS

After the plate and tape have been mounted, to increase the bond shrink wrap film should be tightly wrapped

around the whole cylinder. This will help to reduce the stress on the mounted tape and plate. By wrapping the

plate up this will help build the bond to optimum levels.

CYLINDER AND SLEEVE STORAGE

Storage of mounted cylinders or sleeves should be kept in a controlled environment, excessive heat and humidity

can play a significantly role in adhesion levels which can lead to the tape delaminating;

Cold or air-conditioned areas can reduce the adhesion levels from increasing which can affect the tapes

performance.

COLD FLOW THEORY

This is where you have two products that are designed to not stick to each other in an extreme example…..however if you

subject the two products to enough heat, pressure and time they will generate an affinity for each other and bond

together. What has this got to do with cushion mounting tape? When you are running a long job on a press there is an

element of heat, there is obviously time and there is pressure from the constant pounding of plate pressing down on the

tape, which will increase the affinity of the plate to the cushion and the cushion to the plate cylinder and it could be more

difficult to remove them.

SCAPA CUSHION MOUNT TRAINING MANUAL 10

Updated - 24 June 2019