Page 238 - Training 2019

P. 238

VERSATILITY:

Screen printing is more versatile than traditional printing techniques. The surface does not

have to be printed under pressure, unlike etching or lithography, and it does not have to

be planar (flat). Different inks can be used to work with a variety of materials, such as

textiles, ceramics, wood, paper, glass, metal, and plastic. As a result, screen

printing is used in many different industries, including printed electronics, circuit

board printing, product labels, signs and displays, dense print cover,

snowboard graphics, textile fabrics, thick film/raised image technology,

pinball machines, balloons, clothing, decals, medical devices, scratch cards, solar

panels, etc.

TYPES OF SCREEN PRINTING PROCESSES

FLAT- BED SCREEN PRINTING

CAROUSEL SCREEN PRINTING

CYLINDER or ROTARY SCREEN PRINTING

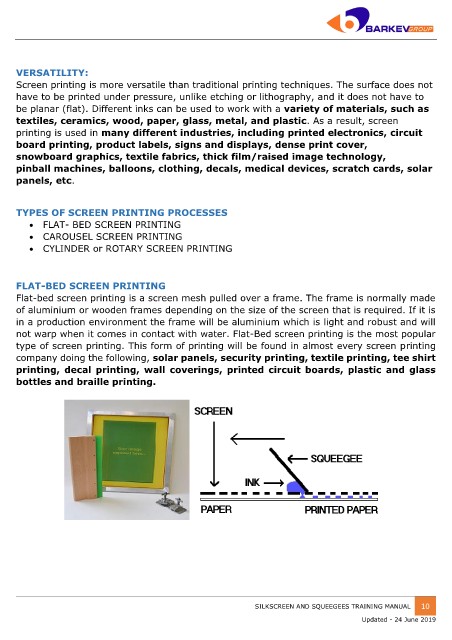

FLAT-BED SCREEN PRINTING

Flat-bed screen printing is a screen mesh pulled over a frame. The frame is normally made

of aluminium or wooden frames depending on the size of the screen that is required. If it is

in a production environment the frame will be aluminium which is light and robust and will

not warp when it comes in contact with water. Flat-Bed screen printing is the most popular

type of screen printing. This form of printing will be found in almost every screen printing

company doing the following, solar panels, security printing, textile printing, tee shirt

printing, decal printing, wall coverings, printed circuit boards, plastic and glass

bottles and braille printing.

SILKSCREEN AND SQUEEGEES TRAINING MANUAL 10

Updated - 24 June 2019