Page 239 - Training 2019

P. 239

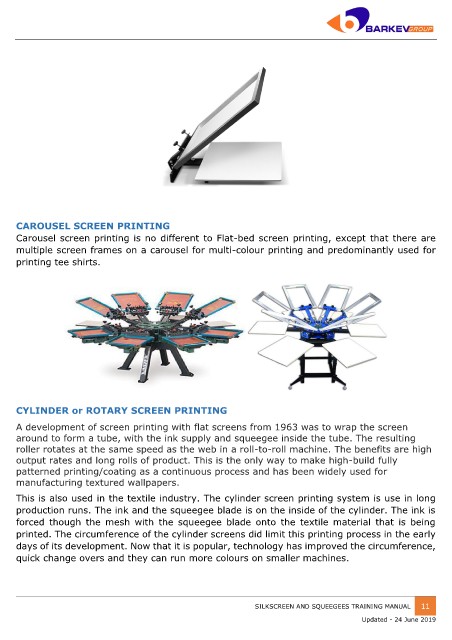

CAROUSEL SCREEN PRINTING

Carousel screen printing is no different to Flat-bed screen printing, except that there are

multiple screen frames on a carousel for multi-colour printing and predominantly used for

printing tee shirts.

CYLINDER or ROTARY SCREEN PRINTING

A development of screen printing with flat screens from 1963 was to wrap the screen

around to form a tube, with the ink supply and squeegee inside the tube. The resulting

roller rotates at the same speed as the web in a roll-to-roll machine. The benefits are high

output rates and long rolls of product. This is the only way to make high-build fully

patterned printing/coating as a continuous process and has been widely used for

manufacturing textured wallpapers.

This is also used in the textile industry. The cylinder screen printing system is use in long

production runs. The ink and the squeegee blade is on the inside of the cylinder. The ink is

forced though the mesh with the squeegee blade onto the textile material that is being

printed. The circumference of the cylinder screens did limit this printing process in the early

days of its development. Now that it is popular, technology has improved the circumference,

quick change overs and they can run more colours on smaller machines.

SILKSCREEN AND SQUEEGEES TRAINING MANUAL 11

Updated - 24 June 2019