Page 17 - mlcc-170613

P. 17

MULTILAYER CERAMIC CAPACITORS

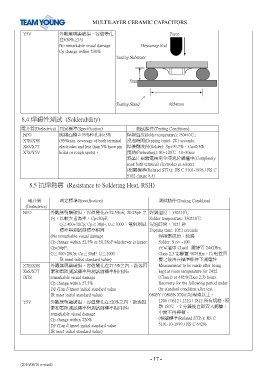

Y5V 外觀無明顯破損,容值變化 Force

在±30%之內

No remarkable visual damage Pressuring Rod →

Cp change within ±30%

Testing Substrate

↘

5mm Capacitor

↗

Testing Stand 90±4mm

8.4 焊錫性測試 (Solderability)

電介質(Dielectrics) 判定標準(Specification) 測試條件(Testing Conditions)

NPO 爬錫面積≧95%和孔洞<5% 焊錫溫度(Solder temperature): 250±10℃;

X7R/X5R (95%min. coverage of both terminal 浸泡時間(Dipping time): 2±1 seconds.

X6S/X7T electrodes and less than 5% have pin 焊接劑成份(Solder): Sn=99.7%,Cu=0.3%.

X7S/Y5V holes or rough spots)。 預熱(Preheating): 80~120℃ 10~30sec

將晶片兩端電極完全浸泡於錫爐中(Completely

soak both terminal electrodes in solder)

(相關標準(Related STD.): JIS C 5101-1998 / JIS C

5102 clause 8.4)

8.5 抗焊熱震 (Resistance to Soldering Heat, RSH)

電介質 判定標準(Specification) 測試條件(Testing Condition)

(Dielectrics)

NPO 外觀無明顯破損,容值變化在±2.5%或 ±0.25pF 之 焊錫溫度︰330±10℃

內,以較大者為準,Cp<30pF, Solder temperature: 330±10℃

Q≧400+20Cp; Cp≧30pF, Q≧1000,電阻測試 浸泡時間︰10±1 秒

標準與測試前標準相同 Dipping time: 10±1 seconds

(No remarkable visual damage 焊接劑成份︰純錫

Cp change within ±2.5% or ±0.25pF whichever is larger: Solder: S n= ~100

Cp<30pF, 在室溫中 Class1 需靜置 24±2Hrs,

Q≧400+20Cp; Cp≧30pF, Q≧1000 Class 2,3 需靜置 48±4Hrs,待電性回

IR meet initial standard value) 覆之後再在標準條件下測電性

X7R/X5R 外觀無明顯破損,容值變化在±7.5%之內,散逸因 Measurement to be made after being

X6S/X7T 素和電阻測試標準與測試前標準相同(No kept at room temperature for 24±2

/X7S remarkable visual damage (Class1) or 48±4(Class 2,3) hours.

Cp change within ±7.5% Recovery for the following period under

DF (Tanδ)meet initial standard value the standard condition after test.

IR meet initial standard value) 0805Y / 0805B XX6(含)規格以上,

Y5V 外觀無明顯破損,容值變化在±20%之內,散逸因 1206 / 0612 / 1210 / 1812 所有規格,預

素和電阻測試標準與測試前標準相同(No 熱 150℃,2 分鐘後立即置入錫爐,

remarkable visual damage 中間不得停頓。

Cp change within ±20% (相關標準(Related STD.): JIS C

DF (Tanδ)meet initial standard value 5101-10-1999 / JIS C 6429)

IR meet initial standard value)

- 17 -

(2016/08/10 revised)