Page 6 - Rear Drum Rebuild

P. 6

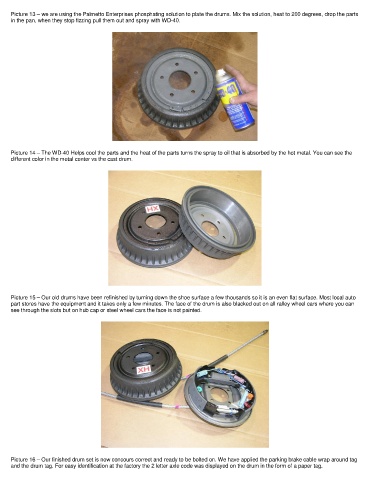

Picture 13 – we are using the Palmetto Enterprises phosphating solution to plate the drums. Mix the solution, heat to 200 degrees, drop the parts

in the pan, when they stop fizzing pull them out and spray with WD-40.

Picture 14 – The WD-40 Helps cool the parts and the heat of the parts turns the spray to oil that is absorbed by the hot metal. You can see the

different color in the metal center vs the cast drum.

Picture 15 – Our old drums have been refinished by turning down the shoe surface a few thousands so it is an even flat surface. Most local auto

part stores have the equipment and it takes only a few minutes. The face of the drum is also blacked out on all ralley wheel cars where you can

see through the slots but on hub cap or steel wheel cars the face is not painted.

Picture 16 – Our finished drum set is now concours correct and ready to be bolted on. We have applied the parking brake cable wrap around tag

and the drum tag. For easy identification at the factory the 2 letter axle code was displayed on the drum in the form of a paper tag.