Page 1 - Caliper Reubild

P. 1

Inline Tube - Caliper Rebuild

One of the largest problems with classic car brakes is that your brake fluid is to be changed every few years. Brake fluid collects moisture over

time, this moisture has water in it and over long periods of time it creates rust. This means the inside of your components are slowly corroding

causing your system to loose effectiveness. This happens with anything that has fluid in it. This includes brake lines, master cylinders, wheel

cylinders, and calipers. If your car has been restored in the last few years keep up on the maintenance and change your fluid every 5 years. If

your car has never been restored and you are wondering how you can improve the brakes, the first step is changing the fluid. By getting the old

fluid out and replacing it with new fluid you eliminate all the moisture which will dramatically increase the effectiveness of the fluid increasing

hydraulic pressure by as much as 20 percent. Next you can replace the old metal brake lines which can rust from the outside from being

exposed to the elements and can also rust from the inside from trapped moisture. Before rebuilding any component you should consider the cost

and labor factor. If the component has never been replaced and it is the correct date coded part for the car it is priceless, if the component has

already been replaced with an aftermarket piece, the time in rebuilding may not be worth the cost of a replacement. An original is always worth

rebuilding. Most components have only a few rubber seals that need to be replaced and they will be a good as new. Rebuild kits are a small

fraction of the component cost but take some labor time to install. If you are working on a driver, seals are quickly replaced in a few minutes, for

a show car a more complete rebuild may be desired. All calipers, wheel cylinders, and masters have manufacture markings and date codes

specific to that year make and model. Replacements have the same shape and function but do not have date codes or manufacture markings.

For a concourse restoration these markings add value and detail to the final restoration. By following the steps below you can rebuild you

components just like an experienced mechanic. Inline Tube offers all the pieces of the rebuild from the rubber seals to complete caliper ready to

bolt onto your classic.

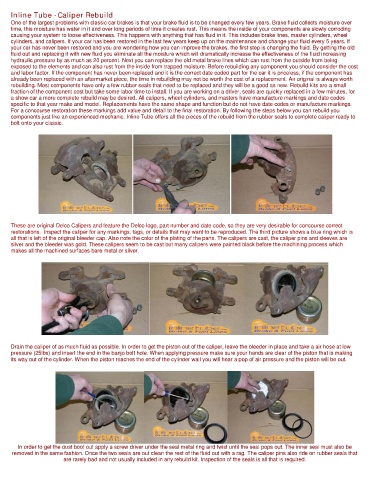

These are original Delco Calipers and feature the Delco logo, part number and date code, so they are very desirable for concourse correct

restorations. Inspect the caliper for any markings, tags, or details that may want to be reproduced. The third picture shows a blue ring which is

all that is left of the original bleeder cap. Also note the color of the plating of the parts. The calipers are cast, the caliper pins and sleeves are

silver and the bleeder was gold. These calipers seem to be cast but many calipers were painted black before the machining process which

makes all the machined surfaces bare metal or silver.

Drain the caliper of as much fluid as possible. In order to get the piston out of the caliper, leave the bleeder in place and take a air hose at low

pressure (25lbs) and insert the end in the banjo bolt hole. When applying pressure make sure your hands are clear of the piston that is making

its way out of the cylinder. When the piston reaches the end of the cylinder wall you will hear a pop of air pressure and the piston will be out.

In order to get the dust boot out apply a screw driver under the seal metal ring and twist until the seal pops out. The inner seal must also be

removed in the same fashion. Once the two seals are out clean the rest of the fluid out with a rag. The caliper pins also ride on rubber seals that

are rarely bad and not usually included in any rebuild kit. Inspection of the seals is all that is required.