Page 2 - Caliper Reubild

P. 2

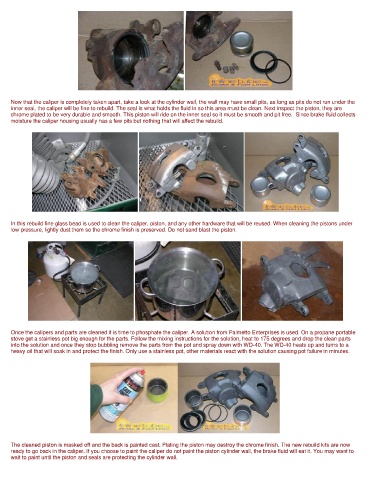

Now that the caliper is completely taken apart, take a look at the cylinder wall, the wall may have small pits, as long as pits do not run under the

inner seal, the caliper will be fine to rebuild. The seal is what holds the fluid in so this area must be clean. Next inspect the piston, they are

chrome plated to be very durable and smooth. This piston will ride on the inner seal so it must be smooth and pit free. Since brake fluid collects

moisture the caliper housing usually has a few pits but nothing that will affect the rebuild.

In this rebuild fine glass bead is used to clean the caliper, piston, and any other hardware that will be reused. When cleaning the pistons under

low pressure, lightly dust them so the chrome finish is preserved. Do not sand blast the piston.

Once the calipers and parts are cleaned it is time to phosphate the caliper. A solution from Palmetto Enterprises is used. On a propane portable

stove get a stainless pot big enough for the parts. Follow the mixing instructions for the solution, heat to 175 degrees and drop the clean parts

into the solution and once they stop bubbling remove the parts from the pot and spray down with WD-40. The WD-40 heats up and turns to a

heavy oil that will soak in and protect the finish. Only use a stainless pot, other materials react with the solution causing pot failure in minutes.

The cleaned piston is masked off and the back is painted cast. Plating the piston may destroy the chrome finish. The new rebuild kits are now

ready to go back in the caliper. If you choose to paint the caliper do not paint the piston cylinder wall, the brake fluid will eat it. You may want to

wait to paint until the piston and seals are protecting the cylinder wall.