Page 10 - PIGNAT catalogue 2020 GB_092020

P. 10

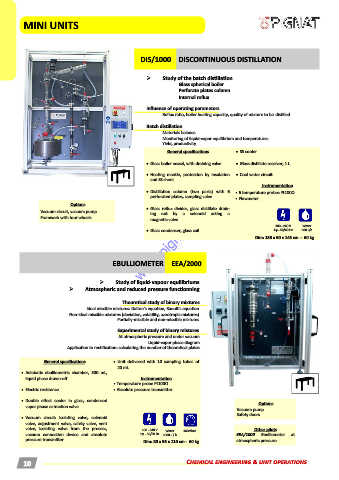

MINI UNITS

DIS/1000 DISCONTINUOUS DISTILLATION

➢ Study of the batch distillation

Glass spherical boiler

Perforate plates column

Internal reflux

Influence of operating parameters

Reflux ratio, boiler heating capacity, quality of mixture to be distilled

Batch distillation

Materials balance

Monitoring of liquid-vapor equilibrium and temperatures

Yield, productivity

General specifications • SS cooler.

• Glass boiler vessel, with draining valve. • Glass distillate receiver, 1 L.

• Heating mantle, protection by insulation • Cool water circuit.

and SS sheet.

Instrumentation

• Distillation column (two parts) with 6 • 6 temperature probes Pt100Ω.

perforated plates, sampling valve. • Flowmeter.

Options

www.pignat.com Dim: 135 x 60 x 145 cm - 60 kg

www.pignat.com drain-

• Glass reflux divider, glass distillate

Vacuum circuit, vacuum pump ing out by a solenoid acting a

Framwork with four wheels. magnetic valve. 1ϕ - 50/60 Hz 500 L/h

Water

100 - 240 V

• Glass condenser, glass coil.

EBULLIOMETER EEA/2000

➢ Study of liquid-vapour equilibriums

➢ Atmospheric and reduced pressure functionning

Theoretical study of binary mixtures

Ideal miscible mixtures: Dalton’s equation, Raoult’s equation

Non-ideal miscible mixtures (deviation, volatility, azeotropic mixtures)

Partially-miscible and non-miscible mixtures

Experimental study of binary mixtures

At atmospheric pressure and under vacuum

Liquid-vapor phase diagram

Application to rectification: calculating the number of theoretical plates

General specifications • Unit delivered with 10 sampling tubes of

20 mL.

• Adiabatic ebulliometric chamber, 300 mL,

liquid phase drawn-off. Instrumentation

• Temperature probe Pt100Ω.

• Electric resistance. • Absolute pressure transmitter.

• Double effect cooler in glass, condensed Options

vapor phase extraction valve. Vacuum pump

Safety doors

• Vacuum circuit: isolating valve, solenoid

valve, adjustment valve, safety valve, vent

valve, isolating valve from the process, 100 - 240 V Water 160mbar Other pilots

vacuum connection device and absolute 1ϕ - 50/60 Hz 1000 L / h EEA/1000 Ebulliometer at

pressure transmitter. atmospheric pressure

Dim: 80 x 55 x 110 cm - 60 kg

10 Chemical engineering & unit operations