Page 69 - PH_Masonry_Final_Ver 1_July 2020

P. 69

Mixing Mortar Using Mechanical Mixers on Site

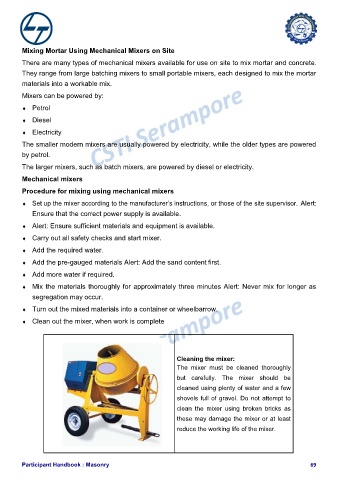

There are many types of mechanical mixers available for use on site to mix mortar and concrete.

They range from large batching mixers to small portable mixers, each designed to mix the mortar

materials into a workable mix.

Mixers can be powered by:

Petrol

Diesel

Electricity

The smaller modern mixers are usually powered by electricity, while the older types are powered

by petrol.

The larger mixers, such as batch mixers, are powered by diesel or electricity.

Mechanical mixers

Procedure for mixing using mechanical mixers

Set up the mixer according to the manufacturer‘s instructions, or those of the site supervisor. Alert:

Ensure that the correct power supply is available.

Alert: Ensure sufficient materials and equipment is available.

Carry out all safety checks and start mixer.

Add the required water.

Add the pre-gauged materials Alert: Add the sand content first.

Add more water if required.

Mix the materials thoroughly for approximately three minutes Alert: Never mix for longer as

segregation may occur.

Turn out the mixed materials into a container or wheelbarrow.

Clean out the mixer, when work is complete

Cleaning the mixer:

The mixer must be cleaned thoroughly

but carefully. The mixer should be

cleaned using plenty of water and a few

shovels full of gravel. Do not attempt to

clean the mixer using broken bricks as

these may damage the mixer or at least

reduce the working life of the mixer.

Participant Handbook : Masonry 69