Page 335 - Programmable Logic Controllers, Fifth Edition - Mobile version

P. 335

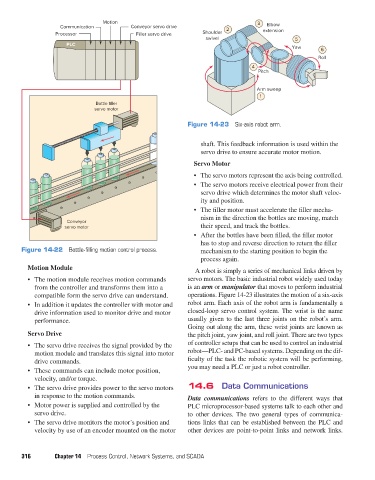

Communication Motion Conveyor servo drive 2 3 Elbow

Processor Filler servo drive Shoulder extension

swivel 5

PLC

Yaw

6

Roll

4

Pitch

Arm sweep

1

Bottle filler

servo motor

Figure 14-23 Six-axis robot arm.

shaft. This feedback information is used within the

servo drive to ensure accurate motor motion.

Servo Motor

• The servo motors represent the axis being controlled.

• The servo motors receive electrical power from their

servo drive which determines the motor shaft veloc-

ity and position.

• The filler motor must accelerate the filler mecha-

nism in the direction the bottles are moving, match

Conveyor

servo motor their speed, and track the bottles.

• After the bottles have been filled, the filler motor

has to stop and reverse direction to return the filler

Figure 14-22 Bottle-filling motion control process. mechanism to the starting position to begin the

process again.

Motion Module

A robot is simply a series of mechanical links driven by

• The motion module receives motion commands servo motors. The basic industrial robot widely used today

from the controller and transforms them into a is an arm or manipulator that moves to perform industrial

compatible form the servo drive can understand. operations. Figure 14-23 illustrates the motion of a six-axis

• In addition it updates the controller with motor and robot arm. Each axis of the robot arm is fundamentally a

drive information used to monitor drive and motor closed-loop servo control system. The wrist is the name

performance. usually given to the last three joints on the robot’s arm.

Going out along the arm, these wrist joints are known as

Servo Drive the pitch joint, yaw joint, and roll joint. There are two types

• The servo drive receives the signal provided by the of controller setups that can be used to control an industrial

motion module and translates this signal into motor robot—PLC- and PC-based systems. Depending on the dif-

drive commands. ficulty of the task the robotic system will be performing,

you may need a PLC or just a robot controller.

• These commands can include motor position,

velocity, and/or torque.

• The servo drive provides power to the servo motors 14.6 Data Communications

in response to the motion commands. Data communications refers to the different ways that

• Motor power is supplied and controlled by the PLC microprocessor-based systems talk to each other and

servo drive. to other devices. The two general types of communica-

• The servo drive monitors the motor’s position and tions links that can be established between the PLC and

velocity by use of an encoder mounted on the motor other devices are point-to-point links and network links.

316 Chapter 14 Process Control, Network Systems, and SCADA

pet73842_ch14_305-332.indd 316 05/11/15 4:27 PM