Page 333 - Programmable Logic Controllers, Fifth Edition - Mobile version

P. 333

Either programmable controllers can be fitted with

input/output modules that produce PID control, or they • Integral gain also provides power, even if the error

is zero (e.g., even when an oven reaches its set-

will already have sufficient mathematical functions to point, it still needs power to stay hot).

allow PID control to be carried out. PID is essentially • Without this base power, the controller will droop

an equation that the controller uses to evaluate the con- and hunt for the set-point.

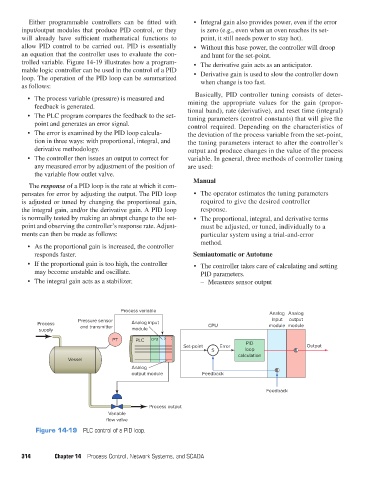

trolled variable. Figure 14-19 illustrates how a program- • The derivative gain acts as an anticipator.

mable logic controller can be used in the control of a PID • Derivative gain is used to slow the controller down

loop. The operation of the PID loop can be summarized when change is too fast.

as follows:

Basically, PID controller tuning consists of deter-

• The process variable (pressure) is measured and mining the appropriate values for the gain (propor-

feedback is generated. tional band), rate (derivative), and reset time (integral)

• The PLC program compares the feedback to the set- tuning parameters (control constants) that will give the

point and generates an error signal. control required. Depending on the characteristics of

• The error is examined by the PID loop calcula- the deviation of the process variable from the set-point,

tion in three ways: with proportional, integral, and the tuning parameters interact to alter the controller’s

derivative methodology. output and produce changes in the value of the process

• The controller then issues an output to correct for variable. In general, three methods of controller tuning

any measured error by adjustment of the position of are used:

the variable flow outlet valve.

Manual

The response of a PID loop is the rate at which it com-

pensates for error by adjusting the output. The PID loop • The operator estimates the tuning parameters

is adjusted or tuned by changing the proportional gain, required to give the desired controller

the integral gain, and/or the derivative gain. A PID loop response.

is normally tested by making an abrupt change to the set- • The proportional, integral, and derivative terms

point and observing the controller’s response rate. Adjust- must be adjusted, or tuned, individually to a

ments can then be made as follows: particular system using a trial-and-error

method.

• As the proportional gain is increased, the controller

responds faster. Semiautomatic or Autotune

• If the proportional gain is too high, the controller • The controller takes care of calculating and setting

may become unstable and oscillate. PID parameters.

• The integral gain acts as a stabilizer. – Measures sensor output

Process variable

Analog Analog

Pressure sensor input output

Process and transmitter Analog input CPU module module

supply module

PT PLC CPU

Set-point Error PID Output

S loop

calculation

Vessel

Analog

output module Feedback

Feedback

Process output

Variable

flow valve

Figure 14-19 PLC control of a PID loop.

314 Chapter 14 Process Control, Network Systems, and SCADA

pet73842_ch14_305-332.indd 314 05/11/15 4:27 PM