Page 329 - Programmable Logic Controllers, Fifth Edition - Mobile version

P. 329

Detergent that represents the weight of the container and

contents.

• The sensor signal is subtracted from the voltage sig-

nal or digital code that has been input to represent

Solenoid the desired weight.

gate • As long as the difference between the input signal

and feedback signal is greater than 0, the controller

Box keeps the solenoid gate open.

• When the difference becomes 0, the controller

Scale

outputs a signal that closes the gate.

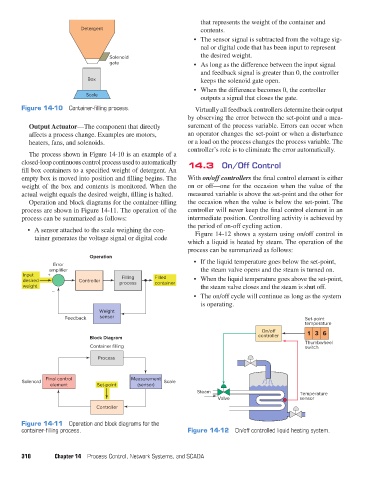

Figure 14-10 Container-filling process. Virtually all feedback controllers determine their output

by observing the error between the set-point and a mea-

Output Actuator—The component that directly surement of the process variable. Errors can occur when

affects a process change. Examples are motors, an operator changes the set-point or when a disturbance

heaters, fans, and solenoids. or a load on the process changes the process variable. The

controller’s role is to eliminate the error automatically.

The process shown in Figure 14-10 is an example of a

closed-loop continuous control process used to automatically 14.3 On/Off Control

fill box containers to a specified weight of detergent. An

empty box is moved into position and filling begins. The With on/off controllers the final control element is either

weight of the box and contents is monitored. When the on or off—one for the occasion when the value of the

actual weight equals the desired weight, filling is halted. measured variable is above the set-point and the other for

Operation and block diagrams for the container-filling the occasion when the value is below the set-point. The

process are shown in Figure 14-11. The operation of the controller will never keep the final control element in an

process can be summarized as follows: intermediate position. Controlling activity is achieved by

the period of on-off cycling action.

• A sensor attached to the scale weighing the con-

tainer generates the voltage signal or digital code Figure 14-12 shows a system using on/off control in

which a liquid is heated by steam. The operation of the

process can be summarized as follows:

Operation

Error • If the liquid temperature goes below the set-point,

amplifier the steam valve opens and the steam is turned on.

Input + Filling Filled

desired Controller process container • When the liquid temperature goes above the set-point,

weight the steam valve closes and the steam is shut off.

–

• The on/off cycle will continue as long as the system

is operating.

Weight

Feedback sensor Set-point

temperature

On/o

13 6

Block Diagram controller

Thumbwheel

Container filling switch

Process

Final control Measurement

Solenoid Scale

element Set-point (sensor)

Steam Temperature

Valve sensor

Controller

Figure 14-11 Operation and block diagrams for the

container-filling process. Figure 14-12 On/off controlled liquid heating system.

310 Chapter 14 Process Control, Network Systems, and SCADA

pet73842_ch14_305-332.indd 310 05/11/15 4:27 PM