Page 327 - Programmable Logic Controllers, Fifth Edition - Mobile version

P. 327

Human machine

interface (HMI)

Host

computer

Communications network

PLC PLC PLC

Machine Machine Machine

Figure 14-6 Distributive control system (DCS).

14.2 Structure of Control Systems • Process actuators that include flow control valves,

pumps, positioning drives, variable speed drives,

Process control normally applies to the manufacturing or clutches, brakes, solenoids, stepping motors, and

processing of products in industry. In the case of a pro- power relays

grammable controller, the process or machine is operated

and supervised under the control of the user program. The Controller

major components of a process control system include the • Makes the system’s decisions based on the input signals

following:

• Generates output signals that operate actuators to

Sensors carry out the decisions

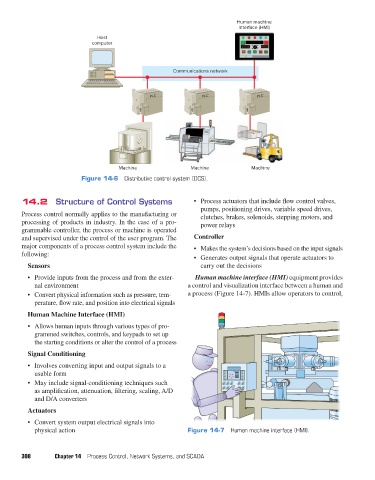

• Provide inputs from the process and from the exter- Human machine interface (HMI) equipment provides

nal environment a control and visualization interface between a human and

• Convert physical information such as pressure, tem- a process (Figure 14-7). HMIs allow operators to control,

perature, flow rate, and position into electrical signals

Human Machine Interface (HMI)

• Allows human inputs through various types of pro-

grammed switches, controls, and keypads to set up

the starting conditions or alter the control of a process

Signal Conditioning

• Involves converting input and output signals to a

usable form

• May include signal-conditioning techniques such

as amplification, attenuation, filtering, scaling, A/D

and D/A converters

Actuators

• Convert system output electrical signals into

physical action Figure 14-7 Human machine interface (HMI).

308 Chapter 14 Process Control, Network Systems, and SCADA

pet73842_ch14_305-332.indd 308 05/11/15 4:27 PM