Page 391 - Programmable Logic Controllers, Fifth Edition - Mobile version

P. 391

Tag Name Value Style Data Type point per minute. The operation of the program can be

Counter_1 { . . . } COUNTER summarized as follows:

Counter_1.PRE 50 Decimal DINT • When the Start_Switch is closed, both the timer and

Counter_1.ACC 0 Decimal DINT counter are enabled.

Counter_1.CU 0 Decimal BOOL • The Total_Bottles counter is pulsed for each bottle

Counter_1.CD 0 Decimal BOOL that passes the Bottle_Sensor.

Counter_1.DN 0 Decimal BOOL • The counting begins and the 1_Min_Timer starts

Counter_1.OV 0 Decimal BOOL timing through its one minute (60000 milliseconds)

Counter_1.UN 0 Decimal BOOL time interval.

Restart_Button 0 Decimal BOOL • At the end of one minute, the timer done bit (DN)

Enter_Limit_Sw 0 Decimal BOOL causes the counter rung to go false.

Exit_Limit_Sw 0 Decimal BOOL • Sensor pulses continue but do not affect the Total_

Conveyor_Contactor 1 Decimal BOOL Bottles counter.

Figure 15-75 Tags created for the Up/Down counter • The number of bottles for the past minute is repre-

program. sented by the accumulated value of the Total_Bottles

counter.

Combining Counter • The sequence is reset by momentarily opening and

closing the Start_Switch.

and Timer Functions

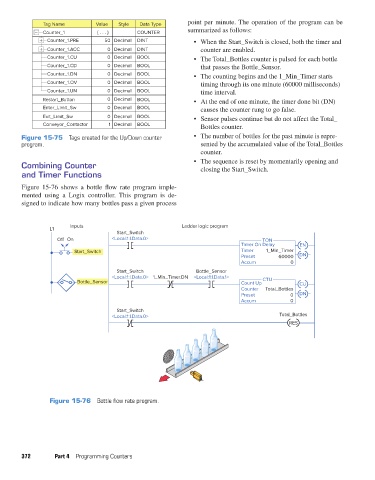

Figure 15-76 shows a bottle flow rate program imple-

mented using a Logix controller. This program is de-

signed to indicate how many bottles pass a given process

Inputs Ladder logic program

L1

Start_Switch

O On <Local:1:I.Data.0> TON

Timer On Delay EN

Start_Switch Timer 1_Min_Timer

Preset 60000 DN

Accum 0

Start_Switch Bottle_Sensor

<Local:1:I.Data.0> 1_Min_Timer.DN <Local:1:I.Data.1>

Bottle_Sensor Count Up CTU CU

Counter Total_Bottles

Preset 0 DN

Accum 0

Start_Switch

<Local:1:I.Data.0> Total_Bottles

RES

Figure 15-76 Bottle flow rate program.

372 Part 4 Programming Counters

pet73842_ch15_333-394.indd 372 03/11/15 7:34 PM