Page 188 - Icon Ridge Presents ORION

P. 188

Milling tools monoblock \ Labelling and marking tools

The perfect needle?

the intricate needle is the heart of the marking tool and the guarantee of a perfect typeface. this enables

marking by a combination of material compaction and material displacement, which we call “rolling”. in

other words, the mark is created by a rounded tip, also known as a “ball”. the ideal radius of this “ball”

varies depending on the material to be marked, the width and depth of the lines and the font size. that’s

why we offer several versions of the needle, to ensure the best marking results.

the needle design is classifi ed according to the angle, radius and eccentricity of the tip. this means that

a needle of 90R10Ex01 design has an angle of 90° at the tip, a radius of 1.0 mm and 0.1 mm eccentricity.

a needle of 90R05Ex00 would thus have an angle of 90°, a radius of 0.5 mm and 0.0 mm eccentricity,

meaning this would be a centred needle.

we would be glad to support you in the search for the optimal needle for your application.

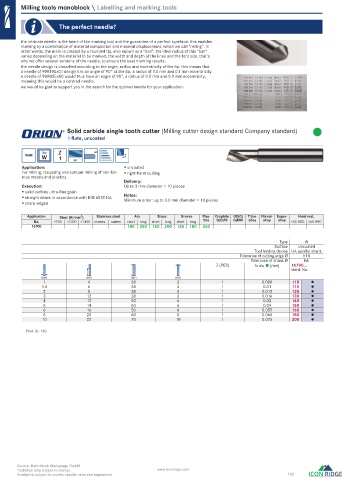

Solid carbide single tooth cutter ( Milling cutter design standard Company standard )

1 flute, uncoated

Typ Z HA

VHM W 1

Application: uncoated

For milling, recessing and contour milling of non-fer- right-hand cutting

rous metals and plastics.

Delivery:

Execution: Up to 3 mm diameter = 10 pieces

solid carbide ultra-fi ne grain

straight shank in accordance with DIN 6535 HA Notes:

Minimum order: up to 3.0 mm diameter = 10 pieces

sharp-edged

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16700 180 350 150 200 145 180 260

Type W

Surface Uncoated

Tool holding device HA parallel shank

Tolerance of cutting edge Ø h10

Tolerance of shank Ø h6

Z (PCS) fz alu (mm) 16700...

Ident. No.

mm mm mm mm

1 4 38 3 1 0.008 110

1.5 6 38 3 1 0.01 115

2 8 38 3 1 0.012 120

3 12 38 3 1 0.016 130

4 12 50 6 1 0.03 140

5 14 50 6 1 0.04 150

6 16 50 6 1 0.055 160

8 20 60 8 1 0.065 180

10 22 70 10 1 0.075 200

Prod. Gr. 150

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 188

0353_EN_2018_KERN[21847583]-m.indd 354 12/17/2018 3:32:27 PM