Page 189 - Icon Ridge Presents ORION

P. 189

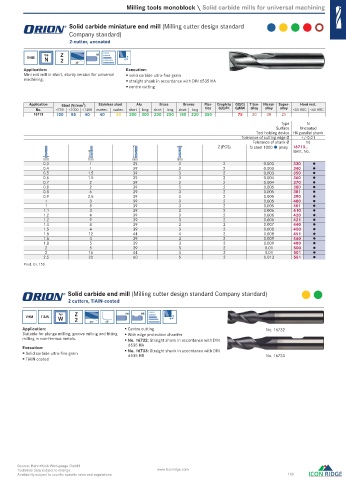

Milling tools monoblock \ Solid carbide mills for universal machining

Solid carbide miniature end mill ( Milling cutter design standard

Company standard )

2-cutter, uncoated

Typ Z HA

VHM

N 2

Application: Execution:

Mini end mill in short, sturdy version for universal solid carbide ultra-fi ne grain

machining. straight shank in accordance with DIN 6535 HA

centre cutting

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16713 100 85 40 40 30 200 300 200 250 180 230 350 75 30 30 25

Type N

Surface Uncoated

Tool holding device HA parallel shank

Tolerance of cutting edge Ø +/-0.01

Tolerance of shank Ø h6

Z (PCS) fz steel 1000 (mm) 16713...

Ident. No.

mm mm mm mm

0.3 1 39 3 2 0.003 330

0.4 1 39 3 2 0.003 340

0.5 1.5 39 3 2 0.003 350

0.6 1.5 39 3 2 0.004 360

0.7 2 39 3 2 0.004 370

0.8 2 39 3 2 0.005 380

0.8 6 39 3 2 0.005 381

0.9 2.5 39 3 2 0.005 390

1 3 39 3 2 0.005 400

1 8 39 3 2 0.005 401

1.1 3 39 3 2 0.006 410

1.2 4 39 3 2 0.006 420

1.2 9 39 3 2 0.006 421

1.4 4 39 3 2 0.007 440

1.5 4 39 3 2 0.008 450

1.5 12 44 4 2 0.008 451

1.6 4 39 3 2 0.009 460

1.8 5 39 3 2 0.009 480

2 5 39 3 2 0.01 500

2 16 44 4 2 0.01 501

2.5 20 60 5 2 0.013 551

Prod. Gr. 150

Solid carbide end mill ( Milling cutter design standard Company standard )

2 cutters, TiAlN-coated

Typ Z HA HB

VHM TiAlN W 2 45°

Application: Centre cutting No. 16732

Suitable for plunge milling, groove milling and fi tting With edge protection chamfer

milling in non-ferrous metals. No. 16732: Straight shank in accordance with DIN

Execution: 6535 HA

Solid carbide ultra-fi ne grain No. 16733: Straight shank in accordance with DIN No. 16733

6535 HB

TiAlN coated

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 189

0353_EN_2018_KERN[21847583]-m.indd 355 12/17/2018 3:32:28 PM