Page 263 - Icon Ridge Presents ORION

P. 263

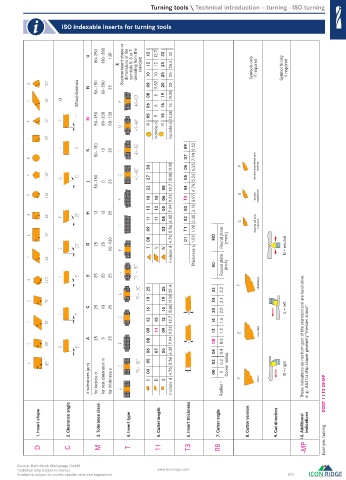

Turning tools \ Technical introduction – turning - ISO turning

ISO indexable inserts for turning tools

80–250 130–380 130

U 12 12.7 32 32

X Scalene insert shape or dimensions of the symbols 5, 6 or 7 deviating from the standard 12 10 12 10 25 25 25.4 25 Symbols only if required Symbol N only if required

Miscellaneous N 50–150 80–200 25 09 08 9.52 8 20 19 20 19.05

O 06 6 16 16

M 50–150 80–200 50–130 05 R 5 15 R 15.88

Incircle d Incircle d

50–150 07 7.94

K 13 25 09 9.52

33 15.88 19.05 06 6.35 double-chamfered and rounded

J 50–150 5 25 27 22 08 12.7 05 04 5.56 4.76

16 16 06 9.52 T3 3.97 double- chamfered

13 13 05 7.94 03 3.18

H 13 13 25

11 11 04 6.35 02 2.38

09 03 5.56 T1 1.98 chamfered and rounded

G 25 25 50–130 08 T V W 4.76 01 1.59 MO Round plate (metr.) N = neutral

Incircle d Thickness s 00 Round plate (inch)

E 25 25 25

25 25 25.4 32 3.2 chamfered

19 19 24 2.4

C 25 13 25 16 15 15.88 19.05 20 2.0 L = left

12 15 12 12.7 16 1.6

09 11 09 9.52 12 1.2 rounded

A 25 5 25 08 7.94 08 0.8 These indications do not form part of the standard and are facultative.

06 05 07 06 6.35 5.56 04 02 0.4 0.2 e. g. -AS3 for chip shaper geometry "medium stress"

± tolerances (m) for incircle d for test dimension m for thickness s 04 C D S 4.76 Incircle d 00 Radius r 0 Corner radius sharp R = right DCMT 11 T3 08-MP

1.Insert shape 2.Clearance angle 3.Tolerance class 4.Insert type 5.Cutter length 6.Insert thickness 7.Cutter angle 8.Cutter version 9.Cut direction 10.Additional indications

D C M T 11 T3 08 -MP Example: turning

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 263

0524_EN_2018_KERN[21847785]-k.indd 525 12/17/2018 3:32:47 PM